- danish

- english

- afrikaans

- albanian

- amharic

- arabic

- armenian

- assamese

- aymara

- azerbaijani

- bambara

- basque

- belarusian

- bengali

- bhojpuri

- bosnian

- bulgarian

- burmese

- catalan

- cebuano

- corsican

- creole

- croatian

- czech

- deutsch

- dhivehi

- dogrid

- dutch

- estonian

- ewe

- filipino

- finnish

- french

- frisian

- galician

- georgian

- greek

- guarani

- gujarati

- haitian_creole

- hausa

- hawaiian

- hebrew

- hindi

- hungarian

- icelandic

- igbo

- indonesian

- irish

- italian

- japanese

- kannada

- khmer

- kinyarwanda

- korean

- kurdish

- kurdish_sorani

- kyrgyz

- lao

- latin

- latvian

- lithuanian

- luganda

- luxembourgish

- macedonian

- maithili

- malay

- malayalam

- maltese

- maori

- marathi

- nepali

- norwegian

- nyanja

- oromo

- pashto

- persian

- polish

- portuguese

- punjabi

- quechua

- romanian

- russian

- samoan

- sanskrit

- scottish_gaelic

- shona

- sindhi

- singapore

- slovak

- slovene

- somali

- spanish

- swahili

- swedish

- tajik

- tamil

- tatar

- telugu

- thai

- turkish

- turkmen

- twi

- ukrainian

- urdu

- vietnamese

- welsh

- yiddish

- yoruba

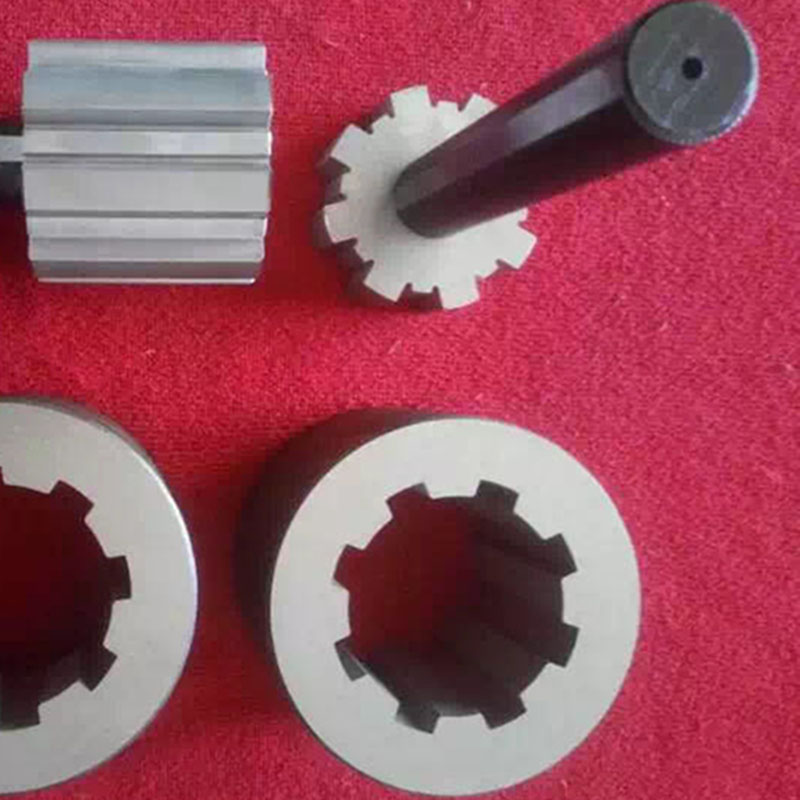

Splain ring gej .

Di diskripshɔn fɔ di prɔdak .

Wi kɔmni kin kɔstɔmayz di nominal dayamita 0.8mm-300mm mɛtrik (M), Amɛrikan (UN , UNC, UNF, UNEF, UNS, NPSC, NPSM, NPSF, NPSI, NPSL, NH), British (BSW, BSF), Jaman standad RP (Din299), G-Tubles, G-Tubes, G-Tubes, G-Tubles, G-Tubles, G-Tubles, G-Tubles, G-Tubles, G-Tubles, G-Tubles, G-Tubles, G-Tubes, G. DIN405), serrated, trapezoidal (Tr, ACME, STUB ACME), gas cylinder (PZ, W), taper (NPT, NPTF, Z, BKG, R, RB, Rc, RP, PT, ZG, WKG, BSPT, ANPT, PTF, etc.), pipe thread gauges (G, PF, PS, BSP, BSPP, etc.), special for sewing machines (SM), st waya thread gej, baysikul (batri motoka) Speshal thread gej (B, BC), ilektrikal aplayans spɛshal trɛd (1BA, 2BA, 3BA, 4BA, 5ba, ɛn ɔda wan dɛn), valv trɛd (5v1, 8v1, ɛn ɔda wan dɛn) 80 ° trɛd (pg7, pg1, pg1, pg13. PG29, PG36 PG42, PG48), API standad gej, API oil paip thread gej, API taper gej, sucker rod thread gages (Cyg13-10, CYG16-10, CYG19-10, Cygg36-10, KGGG36-10, CGGG36-10, CGGG36-10, K. KGG40-10), Oil paip thread gej (LP, TBG, UP TBG, CSG, LCSG, NC).

Wetin mek yu fɔ pik strmachinery splayn gej manifakta .

We i kam pan prɛsishɔn injinɛri, di we aw dɛn kin pik di tul dɛn ɛn di tin dɛn we dɛn kin yuz fɔ mɛzhɔ rili impɔtant. Na di wan dɛn we de pan dɛn wan ya, di splayn ring gej tinap as impɔtant inschrumɛnt fɔ mek shɔ se dimɛnshɔnal akkuracy de insay splayn aplikeshɔn dɛn. Strmachinery, we na wan big splayn gej manifakta, de gi advans sɔlvishɔn dɛn we dɛn mek fɔ mit di industri-spɛsifi k rikwaymɛnt dɛn, we mek dɛn bi di bɛst chuk fɔ pɔshɔnal dɛn we de luk fɔ rilaybiliti ɛn kwaliti.

Wan pan di men rizin dɛn we mek dɛn pik . Stɔraɛn na in eksepshɔnal splayn gej dizayn. Stɔraɛn Employs cutting-edge teknɔlɔji ɛn inovativ injinɛri tɛknik fɔ mek splayn gej dɛn we nɔto jɔs robust bɔt dɛn rili prɛsis. Dɛn dizayn de mek shɔ se dɛn kɔmpitabl wit difrɛn splayn prɔfayl dɛn, we de alaw fɔ kɔrɛkt mɛzhɔmɛnt akɔdin to wan spɛktrum fɔ aplikeshɔn dɛn. Wit di Srmachinery in gej dɛm, injinia dɛm kin ɛkspɛkt supia pefɔmɛns, ridyus di risk fɔ mistek dɛm we kin mek dɛn nɔ gɛt bɔku bɔku prodakshɔn set bak.

Apat frɔm dɛn dizayn dɛn we dɛn dɔn mek, . Stɔraɛn Adheres strikt wan fɔ splayn gej standad. Fɔ fala di standad fɔ di industri na impɔtant tin fɔ mek dɛn kɔntinyu fɔ gɛt kwaliti ɛn trɔst, ɛn Stɔraɛn Rikogniz dis nesisiti. Dɛn splayn gej dɛn de ɛnjɛnɛri fɔ mit strɔng spɛsifikɛshɔn dɛn, ɛn mek shɔ se ɛni prɔdak de gi kɔnsistɛns rizɔlt. Bay we dɛn pik wan manifakta we de prɔyoritɛt standad, klaynt dɛn kin gɛt kɔnfidɛns se dɛn de invɛst insay tul dɛn we de sɔpɔt di ays lɛvɛl dɛn fɔ prɛsishɔn ɛn rilaybiliti.

Dɔn, Stɔraɛn’S komitment fɔ mek di kɔstɔma dɛn satisfay, de mek dɛn difrɛn frɔm kɔmpitishɔn dɛn. Wit wan big renj ɔf opshɔn ɛn di abiliti fɔ kɔstɔmayz dizayn dɛn bays pan spɛshal nid dɛn, dɛn de gi ɛksɛpshɔn sɔpɔt ɔlsay na di bay we dɛn de bay. Dis dedikeshɔn nɔ jɔs de ɛp fɔ mek di yuza ɛkspiriɛns bɛtɛ bɔt i de establish dɛn bak as patna we dɛn trɔst pan prɛsishɔn injinɛri.

Fɔ dɔn, if yu de na di makit fɔ wan kwaliti splayn ring gej, nɔ luk fa pas strmachinery. Wit dɛn supia splayn gej dizayn ɛn unwavering adherence to spline gej standad, na dɛn na di go-to manifakta fɔ pɔshɔnal dɛn we valyu prɛsishɔn ɛn rilaybiliti insay dɛn injinɛri prɔjek dɛn. Pik strmachinery ɛn ɛlevɛt yu mɛzhɔmɛnt akkuracy tide.

Di advantej fɔ yuz splayn ring gej dɛn na prɛsishɔn mɛzhɔmɛnt .

Insay di eria fɔ mɛzhɔ ɛn mek prɛsishɔn, splayn ring gej dɛn dɔn kɔmɔt as impɔtant tul dɛn fɔ mek shɔ se dɛn kɔrɛkt ɛn kwaliti. Dɛn mek dɛn spɛshal gej ya fɔ mɛzhɔ di tut prɔfayl fɔ splayn shaft, we de gi di manifakta dɛn wan rilibul we fɔ chɛk di spɛsifikɛshɔn ɛn tolɛreshɔn dɛn. Insay dis blɔk post, wi go ɛksplɔrɔ di bɛnifit dɛn we yu go gɛt we yu de yuz splayn ring gej, we de sho aw dɛn impɔtant na difrɛn industrial aplikeshɔn dɛn.

Fɔs, wan pan di men bɛnifit dɛn we splayn ring gej dɛn gɛt na dɛn ebul fɔ gi ay akkuracy. We yu de mɛzhɔ di dimɛnshɔn dɛn fɔ di splayn prɔfayl dɛn, prɛsishɔn na di tin we impɔtant pas ɔl. Splayn ring gej dɛn mek to strɛng standad, we de alaw fɔ minimal tolɛreshɔn. Dis ay digri fɔ akkuracy de ridyus di risk fɔ difɛkt ɛn riwɔk, we kin mek i go bifo to ɛnhans prodak kwaliti.

Wan ɔda notabɛl bɛnifit fɔ splayn ring gej na dɛn efyushɔn na gej ɔpreshɔn. Dɛn de gi wan kwik ɛn stret we fɔ inspekshɔn, we de mek di kwaliti kɔntrol prɔses izi. Nɔ lɛk tradishɔnal mɛzhɔmɛnt mɛtɔd dɛn we kin nid intrikɛt sɛtup ɛn kɔlkyulɛshɔn, splayn ring gej dɛn kin gi kwik rizɔlt, we kin rili spid di prodakshɔn tɛm dɛn. Dis efyushɔn na patikyula valyu na ay-volyum manufakchurin ɛnvayrɔmɛnt usay tɛm na di ɛsin.

Plɛnti mɔ, splayn ring gej dɛn kin kɔntribyut to impɔtant kɔnsistɛns insay mɛzhɔmɛnt. We dɛn de yuz dɛn gej ya ɔltɛm, dat de ɛp fɔ mek dɛn establish wan standad akɔdin to di prodakshɔn layn, we de ridyus di vɛryabiliti we dɛn kin kɔz bay manual mɛzhɔmɛnt. Dis kɔnsistɛns na impɔtant tin fɔ di manifakta dɛn we de prɔyoritɛt yunifɔmiti, as i de protɛkt bɛtɛ asɛmbli ɛn funkshɔnaliti fɔ pat dɛn, mɔ na impɔtant aplikeshɔn dɛn lɛk ɔtomotiv ɛn aerospace injinɛri.

Apat frɔm dɛn mɛzhɔmɛnt kapabiliti, splayn ring gej dɛn de ɛp bak fɔ mek di rilaybiliti fɔ kwaliti ɛshyureshɔn prɔses dɛn go bifo. We dɛn impruv dɛn gej ya, di wan dɛn we de mek di tin dɛn kin ebul fɔ no kwik kwik wan ɛni devieshɔn frɔm spɛsifikɛd tolɛreshɔn, we de alaw fɔ kɔrɛkt akshɔn kwik kwik wan. Dis proaktiv aprɔch fɔ kwaliti ɛshyuri kin ɛp fɔ avɔyd kɔst prodakshɔn dilɛys ɛn pɔtɛnɛshɛl fɔlt.

Produk ditel de drɔ .

Pikchɔ dɛn we de na di sayt .

Related PRODUCTS