- danish

- english

- afrikaans

- albanian

- amharic

- arabic

- armenian

- assamese

- aymara

- azerbaijani

- bambara

- basque

- belarusian

- bengali

- bhojpuri

- bosnian

- bulgarian

- burmese

- catalan

- cebuano

- corsican

- creole

- croatian

- czech

- deutsch

- dhivehi

- dogrid

- dutch

- estonian

- ewe

- filipino

- finnish

- french

- frisian

- galician

- georgian

- greek

- guarani

- gujarati

- haitian_creole

- hausa

- hawaiian

- hebrew

- hindi

- hungarian

- icelandic

- igbo

- indonesian

- irish

- italian

- japanese

- kannada

- khmer

- kinyarwanda

- korean

- kurdish

- kurdish_sorani

- kyrgyz

- lao

- latin

- latvian

- lithuanian

- luganda

- luxembourgish

- macedonian

- maithili

- malay

- malayalam

- maltese

- maori

- marathi

- nepali

- norwegian

- nyanja

- oromo

- pashto

- persian

- polish

- portuguese

- punjabi

- quechua

- romanian

- russian

- samoan

- sanskrit

- scottish_gaelic

- shona

- sindhi

- singapore

- slovak

- slovene

- somali

- spanish

- swahili

- swedish

- tajik

- tamil

- tatar

- telugu

- thai

- turkish

- turkmen

- twi

- ukrainian

- urdu

- vietnamese

- welsh

- yiddish

- yoruba

Optik kompoziyt imej levul .

Di diskripshɔn fɔ di prɔdak .

- 1.Application

Di optik kɔmpɔzit imej lɛvɛl na bɔku pipul dɛn de yuz am fɔ mɛzhɔ di grɛdiɛnt dɛn na flat sɔfa ɛn silindrikal sɔfays to ɔrizɔntal dairekshɔn; Di plen ness ɛn stretnes fɔ slaydway ɔ bays fɔ mashin tul ɔ optik mɛkanikal inschrumɛnt ɛn bak di kɔrɛkt we fɔ instɔl pozishɔn fɔ ikwipmɛnt.

- 2.Tɛknikal data .

(1) Ɛni gradyueshɔn valyu: …0.01mm/m

(2) Maks Mezhɔmɛnt Rɛnj: …0~10mm/m

(3) alawns: …1mm/insay wan mita… 0.01mm/m

Insay ful mɛzhɔmɛnt rɛnj…0.02mm/m

(4) Plɛn dɛvyayshɔn pan wok surface…0.0003mm/m

(5) Ɛni gradyueshɔn valyu fɔ di spirit lɛvɛl…0.1mm/m

(6) Wok safa (LW): …165 48mm

(7) Net wet fɔ di inschrumɛnt: …2kgs.

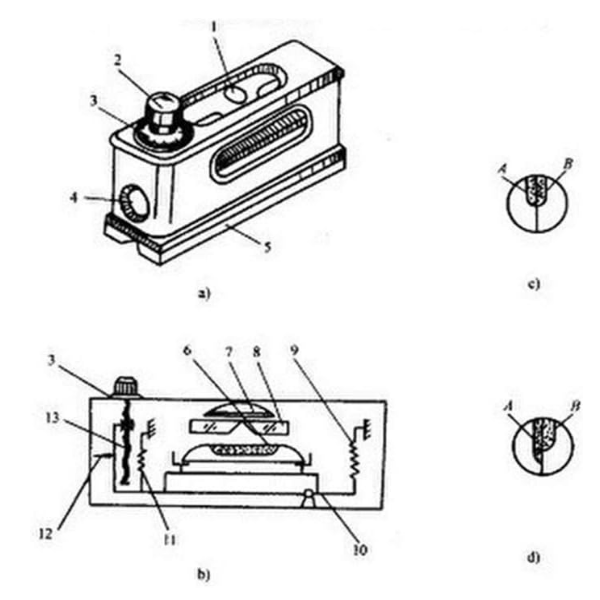

- 3.Strukchɔ fɔ di inschrumɛnt .:

Di kɔmpɔzit imej lɛvɛl men wan na di pat dɛn we de dɔŋ ya lɛk maykro adjɔstmɛnt skru, nat, graduet disk, spirit lɛvɛl, prism, magnifying glas, lev ɛn bak bays wit plain ɛn V wok sɔfays.

- 4.Wɔk prinsipul .:

Di kɔmpɔzit imej lɛvɛl de yuz prism fɔ gɛt di ay bɔbul imej dɛn na di spirit lɛvɛl kɔmpɔzit ɛn magnify fɔ ɛp fɔ mek di ridin akkurayt ɛn yuz lev ɛn maykro skru transmitin sistem fɔ ɛp fɔ mek di ridin sɛnsibul. So if di wok pies wit wan gradient we na 0.01mm/m, i kin rid kɔrɛkt wan na di kɔmpɔzit imej lɛvɛl(di spirit lɛvɛl na di kɔmpɔzit imej lɛvɛl men wan de ple di rol fɔ sho ziro).

- 5.Operet di we aw dɛn de du tin .:

Put di kɔmpɔzit imej lɛvɛl na di wok we de na di wok we dɛn de mɛzhɔ ɛn di gradient we de na di wok we dɛn de mɛzhɔ de mek di tow ay bɔbul imej dɛn nɔ kɔynsayd; Rotate di graduateed disk til di tow air bubble images coincide en ridin kin get kwik kwik wan. Di aktual gradient fɔ di mɛzhɔmɛnt wokpies dɛn kin kɔl bay di fɔmula we de dɔŋ ya .:

Aktual gradient=gradient valyu Fulkrum distans disk ridin

Fox Example: Disk Ridin: 5 Gradients; As dis kɔmpɔzit imej lɛvɛl de fɔks wit in gradient valyu ɛn fulkrɔm distans, dat na grɛdiɛnt valyu: 0.01mm/m ɛn fulkrɔm distans: 165mm.

SO: Akchual gradient=165mm 5 0,01/1000=0,00825mm

- 6.Opereshɔn Notis .:

(1) Bifo yu yuz am, klin di ɔyl dɔst wit petrol ɛn afta dat klin am wit absɔbɛn goz.

(2) Tempracha chenj gɛt big inflɔɛns pan inschrumɛnt ɛn dat mek dɛn fɔ separet am wit ɔt sɔs fɔ avɔyd mistek.

(3) We dɛn de mɛzhɔ, rɔta di disk we dɔn gradyuet te di tow ɛya bɔbul imej dɛn kɔmplit wan kɔynsayd ɛn afta dat dɛn kin tek di ridin dɛn pan ɔl tu di pɔsitiv ɛn nɛgitiv dairekshɔn dɛn.

(4) If dɛn fɛn di inschrumɛnt wit insay kɔrɛkt ziro pozishɔn, dɛn kin ajɔst am; Put di inschrumɛnt pan wan stebul tebul ɛn rɔta di disk we dɔn gradyuet fɔ sɛt di tow ɛya bɔbul imej dɛn kɔynsayd fɔ gɛt fɔs ridin A; Dɔn tɔn di inschrumɛnt bay 180o ɛn put bak to in ɔrijinal ples. Ra-rotate di graduate disk fɔ gɛt di tow ay bɔbul dɛn kɔynsayd fɔ gɛt di sɛkɔn ridin b. So 1/2 (α +β ) na di ziro divyashon fɔ di inschrumɛnt. Luz di tri sɔpɔt skru dɛn na di disk we dɔn gradyuet ɛn prɛs am layt wan wit an di ɛmbos adjɔstmɛnt kap; Rotate di disk bay 1/2 (α +β) fɔ gɛt di ziro dɛvyayshɔn ɛn di pɔynt layn kɔmpɔzit; at las fasten di skru dɛn.

(5) Afta wok, di wok we di inschrumɛnt de wok fɔ klin ɛn kɔt am wit asid fri, anhaydrous, antirɔst ɔyl ɛn antirɔst pepa; Put am insay wud bɔks ɛn afta dat, kip am na klin dray ples.

Hot Tags: Optik kompoziyt imej levul optik kompoziyt imej level suplai cha China optik kompoziyt imej level optik kompoziyt imej level faktri stebul optik kompoziyt imej level

Produkt Paramita .

Teknik Paramita dɛn .

- Plɛt valyu dial 0.01 mm/m

- Mejmɛnt rɛnj 0-10 milimita/mita

- Mama ɛn papa-pikin mistek insay ± 1mm/m+0.01 mm/m

- Di mama ɛn papa dɛn mistek insay di wan ol mɛzhɔmɛnt rɛnj na ± 0. 02 milimita/mita .

- Bench flatness devyashon na 0.003mm

- Sel valyu akyumyuleshɔn standad 0.1 milimita/mita

- Ofis desk saiz 165 x 48 milimita

- Net weit 2.2 Kilogram .

Optik Kompoziyt Imej Lɛvɛl Mentɛnans: Antirɔst Ɔyl & Stɔrej Tips

Prɔpa mentenɛns de mek shɔ se yu optik kɔmpɔzit imej lɛvɛl de kip in 0.01mm/m prɛsishɔn ɛn durabiliti. Fɔ fala dɛn step ya fɔ protɛkt in prism teknɔlɔji ɛn mɛkanikal kɔmpɔnɛnt dɛn .:

1. Dɛn fɔ klin ɛvride fɔ protɛkt di say we yu de kɔmɔt na di wɔl .

Afta yu dɔn yuz am, was di say dɛn we dɛn de wok (V-groove, edj, lens) wit isopropyl alcohol pan klos we nɔ gɛt lint fɔ pul ɔyl ɛn dɔst. Yuz sɔft brɔsh fɔ mek stɛp dɛn we nɔ fayn—nɔ ɛva abraziv, we kin skrach ɔptik pat ɔ damej mɛtal kɔtin. Dis de kip di prɛsishɔn grɔn sɔfays (RA ≤ 0.1μm) we impɔtant fɔ kɔrɛkt ridin.

2. Rutin antirɔst kia fɔ mɛtal pat dɛn .

Wail di granit bays de resist koroshon, metal komponent (skru, leva, hinj) nid protekshon. Put Storaen in nɔ-asid anti-rɔst ɔyl ɛvri 3 mɔnt ɔ afta di mɔstɔ ɛksplɔshɔn .:

Put tintli pan thread ɛn pivot wit dropper, avɔyd fɔ pul pan granit/lɛns.

I de mek dɛn nɔ tek di siz: I de mentɛn di lev mɛkanism sɛnsitiviti (0.001mm prɛsishɔn) fɔ silinda slɔp mɛzhɔmɛnt.

3. Di bɛst we fɔ kip tin dɛn .

Stɔ na di had kes ɔ wan dray kabinɛt fɔ avɔyd tɛmpracha/humiditi damej:

Envayrɔmɛnt: 10°C–30°C, <60% humiditi fɔ protɛkt lens kɔndenseshɔn ɛn ɔptik distɔshɔn.

Pozishɔn: Le flat ɔ rayt insay pad slot; Nɔ ɛva ɔnda ebi tin dɛn fɔ avɔyd fɔ misalign di optik sistɛm.

lɔng tɛm stɔrɔj: ri-apply anti-rɔst ɔyl ɛn ad wan silika paket; Inspek 24 awa bifo yu yuz am, verify zero posishun via 180° rotation kalibreshɔn.

4. Mɔnt funkshɔnal inspekshɔn dɛn .

Chek pefomans ɔltɛm fɔ mek shɔ se yu rili abop pan yu .:

Bubble Clarity: Kɔnfɛm di kɔmpɔzit bɔbul imej alayns smol smol we yu nɔ blur.

Leva muvmɛnt: tɛst maykro-skru fɔ smol smol roteshɔn—stifnɛs signal dɛn nid lɔbrikeshɔn.

Flatnɛs Chɛk: Yuz wan rɛfrɛns plet fɔ validet faktri-kalibrayt flatnɛs (±0.0003mm/m).

5. Storaen in sɔpɔt fɔ lɔng layf .

leva wi ɛkspɛkt savis fɔ mentɛn pik pefɔmɛns .:

Factory recalibreshɔn: Ristɔ 0.01mm/m prɛsishɔn via ISO-sɛtifiket ikwipmɛnt fɔ krichɔl aplikeshɔn dɛn.

Jɛnɛral pat dɛn: Riplesmɛnt kɔmpɔnɛnt dɛn de mek shɔ se dɛn kɔmpit ɛn kip di ɔrijinal akkuracy.

Bay we yu fala dɛn step ya, yu Storaen optik kɔmpɔzit imej lɛvɛl go deliv kɔnsistɛns prɛsishɔn fɔ industrial alaynɛshɔn wok dɛn, bak bay wi 30+ ia injinɛri ɛkspɛriɛns.

Ziro posishun kalibreshɔn fɔ optik kɔmpɔzit imej lɛvɛl: 180° roteshɔn mɛtɔd ɛksplen

Akchual ziro kalibreshɔn impɔtant fɔ yu Storaen optik kɔmpɔzit imej lɛvɛl fɔ mentɛn in 0.01mm/m prɛsishɔn ɛn ±0.0003mm/m flatnɛs. Di 180° roteshɔn we dɛn de yuz de pul di subtil optik ɔ mɛkanikal shift dɛn, we de mek shɔ se dɛn ebul fɔ mɛzhɔ dɛn we dɛn kin abop pan na impɔtant wok dɛn lɛk CNC mashin alaynɛshɔn ɔ aerospace kɔmpɔnɛnt inspekshɔn. Na dis wan na wan strimlayn, step-by-step gayd:

1. Wetin mek yu go kalibrayt?

Impekt, vaybreshɔn, ɔ tɛmpracha fluktueshɔn kin shift di lɛvɛl in ziro rɛfrɛns, we kin mek dɛn mɛzhɔ drift. Kalibreshɔn de rialayn di bɔbul vayl wit di tul in optik prism ɛn lev sistɛm, we de mek shɔ se kɔnsistɛns beslayn fɔ industrial aplikeshɔn dɛn usay 0.001mm divɛyeshɔn dɛn nɔ akseptabl—lɛk fɔ chɛk di mashin tul gayd dɛn ɔ strɔkchɔral fremwɔk dɛn.

2. Sɛtup Rikwaymɛnt dɛn .

Storaen optik kɔmpɔzit imej lɛvɛl (we gɛt wan V-grooved bays ɛn maykro-adjɔst skru)

Certified Precision Reference Flat (ɛgz., wi Storaen granit sɔfayz plet, wit flatnɛs ≤0.0002mm/m)

Wan klin, vaybreshɔn-fri wokbench insay wan tɛmpracha-stabiliz ɛnvayrɔmɛnt (18°C–22°C rɛkɔmɛnd)

3. Step 1: Initial Mɛzhɔmɛnt .

Put di levul lεngth wan pan di rεfrεns flat, alayne di V-groved bays wit di flat in sεntrial aks. Rotate di maykro-adjɔst skru te di kɔmpɔzit bɔbul imej—we di 45° prism sistem mek—pafɛkt wan ɔvalaps na di viewfinder. Rikɔd dis fɔs skel ridin (A), we de sho di kɔrɛnt dɛvyayshɔn frɔm tru ziro.

4. Step 2: 180° Roteshɔn & Sɛkɔn Ridin

Tek tɛm flip di lɛvɛl 180° ɛnd-to-ɛnd we yu de mentɛn in lɔnjitudinal ɔryenteshɔn pan di flat (avɔyd ɛni latɛral muvmɛnt). Adjɔst di maykro-skru bak fɔ alaynɛd di bɔbul pikchɔ ɛn rikodɔ di nyu ridin (B). Di difrɛns Δ = |a – b| I de sho se ziro pozishɔn mistek; Ideal valyu fɔ Storaen lɛvɛl fɔ bi ≤0.005mm/m.

5. Step 3: Mistek kɔrɛkshɔn & verifyeshɔn .

Kalkul di target ziro pozishɔn as di midpɔynt: c = (a + b)/2. Luz di protɛktiv kap na di ziro-adjɔstmɛnt skru (tipikli de nia di bɔbul vayl), de rɔta di skru te di skel rid C, dɔn yu go bak. Ripit step 3–4 te Δ ≤0.002mm/m, mek shɔ se di smɔl smɔl rizid mistek.

6. Pro tips fɔ prɛsishɔn .

Tripul-chɛk Kɔnsistɛns: Du 3 kalibreshɔn saykl, mɔ afta yu transpɔt di lɛvɛl ɔ wok na say dɛn we gɛt tɛmpracha swing, fɔ mek shɔ se di rizɔlt dɛn kin ripit.

Lubrik muv pat dɛm: Put wan drop pan Storaen in nɔ-asid ɔyl to di maykro-skru bifo yu ajɔst am fɔ mek shɔ se i wok fayn fayn wan, i nɔ gɛt baklash ɛn i nɔ de mek i nɔ tay.

Envayrɔmɛnt Kɔntrol: Nɔ kalibrayt nia ɔt sɔs ɔ draft, bikɔs ivin smɔl tɛmpracha gradient dɛn kin afɛkt di granit bays in dimɛnshɔnal stebiliti ɛn introduks mistek.

7. Storaen in kalibreshɔn sɔpɔt .

Ɛvri Storaen optik kɔmpɔzit imej lɛvɛl inklud wan NIST-trasabl kalibreshɔn sɛtifiket, bɔt kwata-kwata in-fild chɛk dɛn kin rɛkɛmand fɔ ebi yus. Wi sɔpɔt inklud .:

Factory recalibreshɔn: Ristɔrin ɔrijinal 0.01mm/m akkuracy yuz laser intafɛromita fɔ ay-stej aplikeshɔn.

Genuine Spare Parts: ADJƆSTMƐNT SKRU DƐN WE YU GO GƐT FƆ DU FƆ YUZ FƆ LƆNG TƐM FƆ YUZ LƆNG TƐM.

Vidio Tutoriɛl & Ɛkspɛkt Gaydɛns: Step-by-stɛp vidio ɛn injinia sɔpɔt fɔ ɛp wit on-sayt kalibreshɔn prosidyuz.

Faynal not dɛn .

Masta di 180° roteshɔn we de mek shɔ se yu Storaen optik kɔmpɔzit imej lɛvɛl de gi di prɛsishɔn we dɛn nid fɔ silindrikal slɔp mɛzhɔmɛnt, mashin tul flatnɛs chɛk, ɛn ɔda impɔtant alaynɛshɔn dɛn. Wit prɔpa kalibreshɔn, dis tul, we bak bay wi 30+ ia injinɛri ɛkspɛriɛns, bi wan indispɛnsabl ɛset insay yu kwaliti kɔntrol wokflɔ, mek shɔ se ɛvri mɛzhɔmɛnt na as rilibul as di fɔs.

Related PRODUCTS