- danish

- english

- afrikaans

- albanian

- amharic

- arabic

- armenian

- assamese

- aymara

- azerbaijani

- bambara

- basque

- belarusian

- bengali

- bhojpuri

- bosnian

- bulgarian

- burmese

- catalan

- cebuano

- corsican

- creole

- croatian

- czech

- deutsch

- dhivehi

- dogrid

- dutch

- estonian

- ewe

- filipino

- finnish

- french

- frisian

- galician

- georgian

- greek

- guarani

- gujarati

- haitian_creole

- hausa

- hawaiian

- hebrew

- hindi

- hungarian

- icelandic

- igbo

- indonesian

- irish

- italian

- japanese

- kannada

- khmer

- kinyarwanda

- korean

- kurdish

- kurdish_sorani

- kyrgyz

- lao

- latin

- latvian

- lithuanian

- luganda

- luxembourgish

- macedonian

- maithili

- malay

- malayalam

- maltese

- maori

- marathi

- nepali

- norwegian

- nyanja

- oromo

- pashto

- persian

- polish

- portuguese

- punjabi

- quechua

- romanian

- russian

- samoan

- sanskrit

- scottish_gaelic

- shona

- sindhi

- singapore

- slovak

- slovene

- somali

- spanish

- swahili

- swedish

- tajik

- tamil

- tatar

- telugu

- thai

- turkish

- turkmen

- twi

- ukrainian

- urdu

- vietnamese

- welsh

- yiddish

- yoruba

Produkt Advantej dɛn .

-

Material Properties ɛn Kɔst Advantej dɛn .

Gud trɛnk ɛn taf .

Kast stɛl na matirial wit ay trɛnk, ɛn in yield trɛnk ɛn tɛnsiɛl trɛnk kin mit di . Rikwaymɛnt fɔ mɔs industrial paip layn sistɛm dɛn. Fɔ ɛgzampul, insay sɔm ay-prɛshɔn stim paip layn dɛn, dɛn kin yuz am fɔ ple di gem . Stilin get valv kin tinap fɔ prɛshɔn we go rich tɛn MPA we nɔ go brok. Dis trɛnk de alaw di . Valv fɔ mek dɛn kɔntinyu fɔ gɛt strɔkchɔral intɛgriti ɔnda harsh wok kɔndishɔn, lɛk fɔ gɛt wata bɔku tɛm we wata kin kam . Hama insay paip layn (prɛshɔn shɔk we kin kam bikɔs ɔf chenj dɛn we kin apin wantɛm wantɛm na di wata we de kɔmɔt na di wata we de kɔmɔt na di bɔdi).

Na di sem tɛm, di wan dɛn we dɛn dɔn pik Stilin gɛt wan patikyula taf bak, we kin absɔb ɛnaji we i impɛtɛkt bay ɛksternal fɔs ɛn avɔyd wan wantɛm wantɛm . Britl fraktrɔs. Dis na wan rili impɔtant sefty garanti fɔ valv dɛn we dɛn dɔn instɔl na envayrɔmɛnt dɛn we kin bi . we kin apin bay aksidɛnt impak, lɛk paip layn sistɛm dɛn nia kɔnstrɔkshɔn sayt ɔ eria dɛn usay industrial . Ikwipmɛnt kin muv bɔku tɛm.Kost-ɛfɛktiv .

We yu kɔmpia am wit sɔm ay-grɛd alɔy stɛl ɔ spɛshal mɛtal matirial, di raw matirial kɔst fɔ kast stɛl na . Rili low. Dis de gi kas stɛl get valv dɛn wan klia prayz advantej insay big-big industrial industri . Aplikeshɔn ɛn kɔst-sɛnsitiv injinɛri prɔjɛkt dɛn. Fɔ ɛgzampul, insay di munisipaliti wata sapɔt sistem, wan big . Nɔmba fɔ di valv dɛn nid fɔ kɔntrol di wata we de flɔ. Di yus fɔ kast stɛl get valv kin ridyus fayn fayn wan . Di matiryal kɔst fɔ di ɔl di prɔjek we i de mek shɔ se i de du di bɛsis pefɔmɛns.

-

Manufakchurin Proses Fleksibul .

Manufakchurin kapabiliti fɔ kɔmpleks shep dɛn .

Di kastin prɔses fɔ kast stɛl kin prodyuz valv kɔmpɔnɛnt dɛn fɔ difrɛn kɔmpleks shep dɛn. fɔ get valv dɛn, . Di intanɛnt flɔ chanɛl, get shep, ɛn valv sit strɔkchɔ ɔl kin bi dizayn wit kɔmpleks jɔyometri dɛn . tru prɛsishɔn kastin. Fɔ ɛgzampul, fɔ mek dɛn ebul fɔ mek di flɔ kwaliti dɛn we di wata gɛt, di flɔ fayn fayn wan, di flɔ . Chanɛl fɔ di get valv kin kɔst insay wan smɔl smɔl kɔntrakt ɔ ɛkspanda shep fɔ ridyus di lokal . Resistance loss of di fluid. Dis fleksibiliti fɔ di manufakchurin prɔses de mek di kɔst stɛl get valv dɛn ebul fɔ . Adapt to difrɛn fluid midia ɛn wok rikwaymɛnt dɛn.

Wid rεnj כf sayz dεm .

Dɛn kin mek kɔst stɛl get valv dɛn insay difrɛn sayz dɛn frɔm smɔl to big dayamita dɛn. Smɔl-dayamita . Dɛn kin yuz kast stɛl get valv fɔ fayn fayn laboratori paip sistem ɔ fɔ kɔntrol smɔl smɔl tin dɛn fɔ smɔl ikwipmɛnt, we big-diamita kast stɛl get valv dɛn (lɛk valv dɛn we gɛt dayamita we na sɔm mita dɛn) dɛn kin yuz insay Big-big wata kɔnsavayshɔn prɔjek ɔ kemikal raw matirial transpɔt paip layn ɛn ɔda tɛm dɛn, we kin mit di nid fɔ difrɛn flɔ ret ɛn paip layn saiz dɛn.

-

Ripairabiliti ɛn Modifiability .

I izi fɔ mek dɛn ripɛnt ɛn chenj di pat dɛn .

Di strɔkchɔ fɔ di kast stɛl get valv na rili simpul, ɛn di kɔnɛkshɔn bitwin di difrɛn pat dɛn . na rili intuitiv. We wan pat pan di valv dɔn pwɛl, lɛk di get we dɛn dɔn wɛr ɔ di valv sit sil . i dɔn pwɛl, dɛn kin pul dɛn pat dɛn ya ɛn chenj dɛn bak izi wan. Fɔ ɛgzampul, insay di ɛvride . Mentɛnans fɔ wan kemikal ɛntapraiz, mentenɛns pɔsin kin pul di get we dɔn pwɛl wit simpul tul dɛn, Riples am wit nyu get ɛn instɔl am bak, so dat di valv go go bak to nɔmal wok kɔndishɔn ɛn Ridyus di ikwipmɛnt dɛn we de dɔŋ di ikwipmɛnt.

Strɔng modifyabiliti .

o If di wok kɔndishɔn fɔ di paip layn sistɛm chenj, lɛk di prɛshɔn we de go ɔp ɔ di flɔ we dɛn nid fɔ flɔ, . Di kast stɛl get valv kin adap to di nyu wok kɔndishɔn tru sɔm modifyeshɔn mɛzhɔ. Fɔ Fɔ ɛgzampul, dɛn kin mek di valv stem strɔng, ɔ dɛn kin chenj di tin we gɛt ay trɛnk silin fɔ mek i go mit fɔ mit . Di tin dɛn we dɛn nid fɔ du fɔ mek dɛn gɛt mɔ prɛshɔn. Dis modifyabiliti de mek di kast stɛl get valv ebul fɔ bɛtɛ adap to di . Prodakshɔn divɛlɔpmɛnt ɛn teknɔlɔji apgrɛdin fɔ di ɛntapraiz we dɛn de yuz fɔ lɔng tɛm.

Produkt Pɔfɔmɛnshɔn .

-

Fluid kɔntrol pefɔmɛns .

Flɔ Karakta dɛn .

o We di kast stɛl get valv dɔn opin ful wan, in flɔ chanɛl dɔn ɔlmost stret tru, ɛn di fluid . Resistance coefficient na rili smɔl. akɔdin to ɛkspirimɛnt data, ɔnda di sem paip dayamita ɛn . Flow kondishon, di resistans loss of cast steel gate valves de plenti low pas di wan of som oda kain . di valv dɛn lɛk stɔp valv dɛn. Fɔ ɛgzampul, insay wata paip layn dɛn, di flɔ kɔfishin (CV valyu) fɔ di kast . stɛl get valv dɛn we dɛn opin ful wan kin rich wan ay levul, we kin ajɔst to efyushɔn transpɔt fɔ . Big big flɔ ɛn ɛp fɔ mek di transpɔt efyushɔn fɔ di wan ol paip layn sistɛm bɛtɛ.

Rigyuleshɔn Pɔfɔmɛnshɔn .

o Pan ɔl we dɛn kin yuz get valv dɛn we dɛn kin yuz ɔltɛm na stet dɛn we opin ɔ we dɔn fulɔp, we dɛn kɔl kas stɛl get valv dɛn kin . Dɔn bak, ple wan patikyula pat pan sɔm tɛm dɛn usay dɛn nid fɔ gɛt flɔ rigyuleshɔn. Na bay we dɛn de kɔntrol di opin we dɛn de opin . ayt fכ di get, kכs rεguleshכn fכ fכ fכm fכ fכm fכ fכm kin apin. Bɔt, in rigyuleshɔn akkuracy na . Rili low kompare to speshal regulating valves lek bol valv o regulating valves. Na sɔm pipul dɛn . Indastrial prɔses dɛn we nɔ nid patikyula ay flɔ akkuracy, lɛk simpul kol wata flɔ . Rate Control, Cast Steel Gate Valves kin mit di bɛsik rigyuleshɔn nid dɛn.

-

Silin Pɔfɔmɛnshɔn .

Statik siling pefɔmans .

o Di sil bitwin di valv sit ɛn di get na di kast stɛl get valv na di ki. insay wan statik stet, . Wan gud statik siling ifɛkt kin apin tru rizin sɛlɛkshɔn fɔ silin matirial ɛn silin . strɔkchɔ dizayn, lɛk di yus fɔ rɔba siling ring dɛn wit gud ɛlastik ɔ wan kɔmbaynshɔn fɔ mɛtal ɛn Non-metal silin. Fɔ ɛgzampul, insay wan gas transmishɔn paip, wan kast stɛl get valv kin ifɛktiv wan . Prɛvent gas lik na wan klos stet, ɛn in siling pefɔmɛns kin rich wan rili ay levul, mitin Strikt sefty standad.

Dynamic Siling Pɔfɔmɛnshɔn .

o Di sil we de na di valv stem na impɔtant tin bak. Kast stɛl get valv dɛn kin yuz pak sil dɛn we dɛn kin pak. Na bay we yu ful-ɔp . wit silin pak dεm lεk asbest εn grafayt, εn mach wit aprכpriet pak gland strכkchכ dεm, i kin ebul fכ mek di mεdiכm fכ lik along di valv stem di tεm we di valv de muv . branch. Insay wan ay-tɛmpracha ɛn ay-prɛshɔn wok ɛnvayrɔmɛnt, di rizin sɛlɛkshɔn fɔ . ay-tɛmpracha ɛn ay-prɛshɔn rɛsistɛns pak matirial kin mek shɔ se di dinamik silin pefɔmɛns fɔ . Di valv stem. Fɔ ɛgzampul, insay di ay-tɛmpracha ɔyl paip layn na wan ɔyl rifinɛri, di valv stem sil fɔ . Wan kast stɛl get valv kin wok stably fɔ lɔng tɛm.

-

Mekanikal prɔpati dɛn .

Prɛshɔn rɛsistɛns .

o Di valv bɔdi ɛn di men tin dɛn we de insay wan kast stɛl get valv kin ebul fɔ bia wit ay prɛshɔn. Pas Rizin strɔkchɔral dizayn ɛn matirial sɛlɛkshɔn, in prɛshɔn rɛsistɛns lɛvɛl kin rich difrɛn . di lεvεl frכm di lכw prεshכn (lεk PN10) to ay prεshכn (lεk PN420). Insay di prɛshɔn tɛst, di kast . Steel Gate Valve kin mentɛn strɔkchɔral stebiliti na di prɛshɔn we dɛn dɔn spɛsifa maltipul (lɛk 1.5 tɛm di tɛm di . wok prɛshɔn) we nɔ gɛt difɔmeshɔn ɔ lik we pɔsin kin si. Dis prɛshɔn rɛsistɛns de mek dɛn ebul fɔ yuz am insay . Pipeline systems of difrɛn prɛshɔn lɛvɛl dɛn, lɛk ɔban gas ay-prɛshɔn transmishɔn paip layn dɛn ɛn . Indastrial stim paip layn dɛn.

Tempracha resistans .

o Kast stɛl matirial dɛnsɛf gɛt sɔm tɛmpracha rɛsistɛns. Jɛnɛral wan, kast stɛl get valv dɛn . kin wok nכmal wan na di tεmprachכ rεnj fכ - 29°C - 425°C. Insay ay tempɔret ɛnvayrɔmɛnt, di chenj dɛn we de insay . I mekanik prɔpati dɛn rili smɔl, we kin mek shɔ se di nɔmal opareshɔn fɔ di valv. Fɔ Fɔ ɛgzampul, insay di stim paip na wan tɛmal pawa plant, di tɛmpracha kin ay lɛk ɔndrɛd digri. Di kast stɛl get valv kin stably kɔntrol di flɔ fɔ stim na so ay tempɔret, ɛn i nɔ go . Kɔz fayl bikɔs ɔf sɔft ɔ ridyus trɛnk fɔ di matirial.

Opareshɔnal sɛnɛriɔ dɛn .

-

Energy industry .

Ɔyl ɛn gas ɛkstrakshɔn ɛn transpɔt .

o Na di say we dɛn de pul ɔyl, dɛn kin yuz kɔst stɛl get valv dɛn na wɛl-hɛd divays dɛn fɔ kɔntrol di ɔtflɔ . di krud ɔyl ɛn nɛtrɔl gas. Insay ay-prɛshɔn, san san krud ɔyl paip, i kin ebul fɔ bia wit ay prɛshɔn . ɛn wan patikyula digri fɔ abrashɔn fɔ mek shɔ se dɛn transpɔt krud ɔyl fayn fayn wan frɔm di ɔyl wɛl to di . Rifaynari. Insay nɛtrɔl gas paip, dɛn kin yuz kɔst stɛl get valv dɛn as valv dɛn we dɛn kɔt, we kin bi . Kwik kwik kwik wan we dɛn nɔ gɛt ɛnitin fɔ du wit di tin dɛn we go apin to dɛn fɔ mek dɛn nɔ gɛt natura gas lik ɛn mek shɔ se dɛn gɛt transpɔt fɔ kɛr dɛn go.

Pawa Jɛnɛreshɔn .

o Insay tɛmal pawa plant dɛn, dɛn kin yuz kɔst stɛl get valv dɛn bɔku bɔku wan na stim paip layn dɛn, kol wata paip layn dɛn, ɛn fiul paip layn dɛn. Insay stim paip, i de kɔntrol di flɔ we ay-tɛmpracha de flɔ ɛn . ay-prɛshɔn stim fɔ drɛb di stim tɔbayn fɔ mek ilɛktrishɔn; In kol wata paip layn dɛn, i . Adjɔst di flɔ fɔ kol wata fɔ mek shɔ se di kol ifɛkt we di jenɛra sɛt gɛt; Na kol ɔ fiul ɔyl . Pipelines, i de akt lɛk kɔntrol valv fɔ ajɔst prɛsis fiul saplai.

-

Kεmikכl Indastri .

Kεmikכl Raw Materials transpכt εn Riakshכn prכsεs kכntrכl .

o Insay di transpɔt paip layn fɔ kemikal raw matirial, dɛn kin yuz kɔst stɛl get valv fɔ kɔntrol di fכlכ fכ difrεn kεmikכl raw mεtirial dεm, lεk asid, alkali, sכlt sכlushכn εn כrganik kεmikכl. Na di inlet ɛn ɔlt paip layn dɛn fɔ kemikal riaktɔ, i kin kɔntrol di inlet ɛn ɔlt fɔ di Riakshɔn matirial fɔ mek shɔ se di kemikal riakshɔn dɛn go fayn fayn wan. Fɔ ɛgzampul, insay di fɛtilayza . prodakshɔn prɔses, dɛn kin yuz kast stɛl get valv fɔ kɔntrol di transpɔt ɛn riakshɔn prɔses fɔ . Raw matirial dɛn lɛk amonia ɛn sɔlfɔrik asid.

Kεmikכl prodakt stכrej εn lod εn כnlod .

o Na di say we dɛn de kip di tank dɛn na di Kɛmikɛl Prodakt dɛn, dɛn kin put stɛl get valv dɛn . dɛn dɔn instɔl na di inlet ɛn ɔlt paip layn dɛn fɔ kɔntrol di lod ɛn ɔndo we dɛn de pul di prɔdak dɛn. We Di lod ɛn ɔndo we dɛn de pul di likwid kemikal prɔdak dɛn (lɛk mɛtanɔl, ɛtɛlin glykol, ɛn ɔda wan dɛn), ɛn ɔda tin dɛn), I kin ebul fɔ bia di prɛshɔn difrɛns bitwin di tank trak ɛn di stɔrɔj tank fɔ mek shɔ se di sef . ɛn akkuracy fɔ di loading ɛn unloading prɔses.

-

Wata Tritmɛnt Indastri .

Raw wata transpɔt ɛn prɛtritmɛnt .

o Insay di raw wata transpɔt paip layn na di ɔban wata saplai sistem, di kast stiɛl get valv dɛn de . Dɛn kin yuz am fɔ kɔntrol di wata we dɛn kin it na wata sɔs lɛk riva ɛn lek. in di prɛtritmɛnt stej fɔ . Di wata tritmɛnt plant, lɛk kɔagulɛshɔn, sɛdimɛnt, filtreshɔn ɛn ɔda prɔses, i de kɔntrol Di wata we de flɔ bitwin difrɛn tritmɛnt yunit dɛn fɔ mek shɔ se di kwaliti ɛn di efyushɔn fɔ di wata tritmɛnt.

Siwej tritmɛnt ɛn risaykul .

o Insay siwej tritmɛnt plant dɛn, dɛn kin yuz kɔst stɛl get valv dɛn fɔ kɔntrol di flɔ we dɔti de flɔ insay difrɛn difrɛn Tritmɛnt link dɛn (lɛk gril, aeration tank, sedimɛnt tank, ɛn ɔda tin dɛn). insay siwej risaykul sistem dɛn, . Dɛn kin yuz am bak fɔ kɔntrol aw fɔ sheb ɛn yuz bak di wata we dɛn dɔn yuz bak, lɛk fɔ mek grɔn grɔn . Irigashɔn, industrial kɔling wata riplenishmɛnt, ɛn ɔda tin dɛn.

-

Bildin ɛn Munisipal Ɛnjinia .

bildin wata saplai ɛn drenaj sistem .

o Insay di wata saplai ɛn drenaj paip layn dɛn na bildin dɛn, dɛn de yuz kɔst stɛl get valv dɛn as di men kɔntrol valv dɛn fɔ kɔntrol di sapɔt fɔ domestik wata, faya wata, ɛn ɔda tin dɛn na di wata sapɔt sistɛm na Di bildin dɛn we gɛt ay ay ay ay wan, i kin ebul fɔ bia wit wan patikyula haydrostatik prɛshɔn fɔ mek shɔ se di wata nɔ go chenj . gi. Insay di faya protɛkshɔn sistem, dɛn kin opin ɔ lɔk di kɔst stɛl get valv dɛn ɔ lɔk am kwik kwik wan fɔ gi . Naf wata fɔ faya protɛkshɔn ikwipmɛnt.

Munisipal wata saplai ɛn drenaj ɛn itin paip nɛtwɔk .

o Insay di siti in wata saplai ɛn drenaj paip nɛtwɔk, dɛn kin yuz kɔst stɛl get valv fɔ kɔntrol di siwej Dischaj ɛn ren wata kɔllɛkshɔn. Insay di ɔban itin nɛtwɔk, i de kɔntrol di distribyushɔn ɛn . Sakyuleshɔn fɔ ɔt wata fɔ mek shɔ se di ɔt nid fɔ di pipul dɛn we de de ɛn di ɛntapraiz dɛn. na di siti dɛn . Ɔndagrɔn intagreted paip layn kɔridɔ, kast stɛl get valv na impɔtant paip layn kɔntrol ikwipmɛnt, we de mek am izi fɔ mek dɛn mentenɛns ɛn manej di paip layn sistɛm.

STAINLESS STEEL GET VALV DƐN .

-

Eksɛlɛnt kɔrɛshɔn rɛsistɛns .

Resistant to corrosion by difrɛn kemikal midia .

o stenlɛs stiɛl get valv dɛn gɛt alɔy ɛlimɛnt dɛn lɛk kromiɔm (CR) ɛn nikel (NI). Krɔmiɔm . I kin mek wan dense kromiɔm ɔksayd protɛktiv fim na di sɔfays fɔ stenlɛs stiɛl. Dis fim gɛt . Di abiliti fɔ ripɛnt dɛnsɛf ɛn i kin ebul fɔ mek ɔksijɛn, wata ɛn ɔda midia nɔ kɔntakt di . Base metal, so dat de agens koroshon. Fɔ ɛgzampul, insay wan si wata ɛnvayrɔmɛnt we gɛt klorayd ayɔn . (CL⁻), 316L stenlɛs stiɛl get valv dɛn kin rili rɛsist pit ɛn kres kɔrɛshɔn we klorayd kin mek ayɔn dɛn. Dis na bikɔs in ay nikel kɔntinyu de ɛp di matirial in tolɛreshɔn to klorayd ayɔn dɛn. na di . Dɛn kin yuz kemikal industri, stenlɛs stiɛl get valv fɔ handel difrɛn asid, alkali, ɛn sɔl . Sɔlv dɛn. Fɔ ɛgzampul, insay paip layn fɔ kɔnvɛy ayli kɔrosiv midia lɛk naytrik asid ɛn sɔdiɔm . Hydroxide, dem kin maintain gud pefomans fo long taim.

Anti-envayrɔmɛnt kɔrɛshɔn .

o stenlɛs stiɛl get valv dɛn sho gud kɔrɛshɔn rɛsistɛns insay difrɛn natura ɛn industrial Envayrɔmɛnt dɛn. Insay humid marin ɛnvayrɔmɛnt, i nɔ go rɔst kwik kwik wan lɛk ɔdinari kabɔn stiɛl valv dɛn; Insay industrial ɛnvayrɔmɛnt dɛn we dɛn dɔn dɔti bay asid gas dɛn lɛk sɔlfɔ dayɔgzayd (SO2), i kin kɔntinyu fɔ mentɛn bak . di smol smol we di surface de smooth en di integriti of di structure. Dis ebul fɔ tinap agens di envayrɔmɛnt . Kɔroshɔn de mek stenlɛs stiɛl get valv dɛn we dɛn kin yuz bɔku bɔku wan na ɔda paip sistem ɛn paip layn layout dɛn Na industrial plant dɛn.

-

Di fayn fayn tin dɛn we yu de du ɛn di bɛnifit dɛn we yu go gɛt we yu de klin .

Smooth surface ɛn i izi fɔ klin .

o Di say we di get valv dɛn we gɛt stenlɛs stiɛl dɔn dɔn ay, ɛn di say we i de rɔf na di wɔl kin ɔltɛm . Rich wan lɔw valyu. Dis kin mek i nɔ izi fɔ di mɛdiɔm fɔ kip dɔti ɛn dɔti tin dɛn we i de flɔ . Insay di valv. ɛn insay di tɛm dɛn we dɛn nid fɔ klin, lɛk di it ɛn drink prɔsesin . Indastri, in smol smol say kin izi fɔ klin. Fɔ ɛgzampul, insay wan milk prɔsesin prodakshɔn layn, . Stenlɛs stiɛl get valv dɛn kin pul di tin dɛn we de insay di milk kwik kwik wan we dɛn de klin . bitwin prodakshɔn batch fɔ avɔyd baktriyal gro ɛn krɔs kɔntaminɛshɔn.

Kɔmplit wit di fayn fayn tin dɛn we dɛn dɔn plan fɔ du .

o bikɔs ɔf di kemikal stebiliti ɛn nɔ-tɔksiti fɔ stenlɛs stiɛl insɛf, stenlɛs stiɛl get valv dɛn Mit di strikt hajɛns standad fɔ industri dɛm lɛk it ɛn mɛrɛsin. insay drag prodakshɔn, i go . nɔ rilis bad bad mɛtal ayɔn ɔ ɔda dɔti tin dɛn insay di drɔgs, mek shɔ se di klin ɛn kwaliti fɔ . Di drɔgs dɛn. Insay di fluid kɔntrol fɔ di mɛdikal divays dɛn, lɛk di valv dɛn na di ɔspitul disinfɛkshɔn ikwipmɛnt . ɛn infuzhɔn ikwipmɛnt, di hajɛnik pefɔmɛns fɔ stenlɛs stiɛl get valv dɛn na impɔtant tin Fɔ mek shɔ se dɛn gɛt mɛdikal sef.

-

Apiarens ɛn di tɛm we pɔsin go ebul fɔ du am .

Nays apia dizayn .

o stenlɛs stiɛl matirial dɛn gɛt natura mɛtal luster. Afta we dɛn dɔn trit am na di wɔl lɛk polish, . Di we aw dɛn luk di stenlɛs stiɛl get valv dɛn fayn ɛn gɛt fri-an. in sɔm tɛm dɛn we gɛt ay . Rikwaymɛnt fɔ di apinɛns fɔ di ikwipmɛnt, lɛk di mɔdan fud prɔsesin plant dɛn, wata sapɔt ɛn Drenaj sistem fɔ ay-ɛnd ɔtel dɛn, stenlɛs stiɛl get valv dɛn kin ɛp fɔ mek di wan ol fayn fayn tin dɛn fayn . Pipeline system ɛn kɔdinɛt wit di envayrɔmɛnt we de rawnd.

Fɔ lɔng tɛm fɔ lɔng tɛm .

o Di durabiliti fɔ stenlɛs stiɛl get valv dɛn nɔ jɔs de sho insay dɛn kɔrɛshɔn rɛsistɛns, bɔt bak insay dɛn strɔkchɔral stebiliti di tɛm we dɛn de yuz am fɔ lɔng tɛm. Ɔnda nɔmal wok kɔndishɔn, stenlɛs . Steel gate valves kin yuz fɔ bɔku ia witout obvious performance degradation. Fɔ ɛgzampul, insay Di wata saplai ɛn drenaj sistem fɔ wan bildin, stenlɛs stiɛl get valv dɛn kin wok fayn fayn wan insay di savis layf fɔ di bildin fɔ bɔku bɔku ia afta dɛn dɔn instɔl am, we dɔn ridyus di trɔbul ɛn di kɔst fɔ . frɛkuɛnt valv riplesmɛnt.

Produkt Pɔfɔmɛnshɔn .

-

Fluid kɔntrol pefɔmɛns .

Akkurat Flɔ Rɛgyuleshɔn .

o stenlɛs stiɛl get valv dɛn kin gi rili kɔrɛkt kɔntrol insay sɔm tɛm dɛn usay flɔ Rigyuleshɔn nid fɔ de. Di linya muvmɛnt fɔ in get plet kin ajɔst rili fayn rigyuleshɔn . fɔ di flɔ. We yu kɔmpia am wit kast stɛl get valv dɛn, stenlɛs stiɛl get valv dɛn kin bɛtɛ mit di . nid dɛn insay sɔm tɛm dɛn usay dɛn nid fɔ flɔ akkurayt, lɛk di batch prɔses fɔ fayn . Kεmikכl כ di fכluid εkspεriεns divays na di labכtכri. Fɔ ɛgzampul, insay di prɔses fɔ drɔg . Fɔmyuleshɔn Insay famasitik kɔmni dɛn, dɛn kin gi sɔm kayn drɔg sɔlv kɔrɛkt wan kɔrɛkt wan . bay we dɛn de kɔntrol di opin digri fɔ di stenlɛs stiɛl get valv kɔrɛkt wan.

Transmishɔn we de mek pɔsin ebul fɔ transmit di wata fayn fayn wan .

o Insay di ful opin stet, di flɔ chanɛl na di stenlɛs stiɛl get valv nɔ gɛt ɛnitin fɔ ambɔg am ɛn di . Fluid resistans na smɔl tin. I flɔ kɔfishin (CV valyu) ikwal to di wan we di kast stɛl gɛt . get valv ɛn ivin bɛtɛ insay sɔm kes dɛn. Insay di likwid delivri paip layn dɛn na di it ɛn drink . Indastri, lɛk di kan prodakshɔn layn fɔ drink dɛn, stenlɛs stiɛl get valv dɛn kin Efishinli deliv likwid, mek shɔ se di kwik ɔpreshɔn fɔ di prodakshɔn layn de wok kwik kwik wan, ɛn ridyus di ɛnaji . Lɔs fɔ di likwid na di valv.

-

Silin Pɔfɔmɛnshɔn .

High-level siling rilaybiliti .

o Di silin sɔfays fɔ di stenlɛs stiɛl get valv kin ɔltɛm adopt advans siling teknɔlɔji . ɛn matirial dɛn. Fɔ ɛgzampul, ay-perfɔmans silin matirial dɛn lɛk polytetrafluoroethylene (PTFE .) ɔ dɛn kin yuz rɔba we dɛn mek wit rɔba. Dɛn matirial ya gɛt gud ɛlastik ɛn kɔrɛshɔn rɛsistɛns ɛn dɛn kin ebul fɔ . Mek shɔ se di silin ifɛkt ɔnda difrɛn tɛmpracha ɛn prɛshɔn kɔndishɔn dɛn. Na di paip layn sistem . Fɔ di ay-tɛmpracha it kuk ikwipmɛnt, di sil fɔ di stenlɛs stiɛl get valv kin mek Stiam lik ɛn mek shɔ se di sef ɛn nɔmal opareshɔn fɔ di ikwipmɛnt.

Lɔng tɛm stebul silin layf .

o bikɔs ɔf di stebiliti fɔ stenlɛs stiɛl matirial ɛn di durabiliti fɔ silin matirial dɛn, di . Siling pefomans fɔ stenlɛs stiɛl get valv kin stil stebul we dɛn de yuz am fɔ lɔng tɛm. na di . Aseptik paip layn sistem fɔ di famasitik industri, in silin pefɔmɛns kin mek shɔ se afta dat afta . Bɔku opin ɛn klosing opareshɔn dɛn, i stil de mek dɛn nɔ ebul fɔ kam insay di maykro ɔganism dɛn ɛn di dɔti tin dɛn, i de mek di layf we di valv de liv lɔng, ɛn i de ridyus di frɛkuɛns we dɛn de mek ɛn chenj am . Sil dɛn.

Kɔntakt wi .

Storaen (Cangzhou) International Trading Co.stands tall as beacon of excellence in di manufacturing realm, we de na di siti we de wok tranga wan na Botou, Chaina. Dis big big kɔmni we dɛn rili rɛspɛkt dɔn gɛt bɔku bɔku industrial prɔdak dɛn, ɛn i dɔn gɛt wan fayn fayn nem fɔ in kɔmitmɛnt we nɔ de chenj fɔ kwaliti ɛn prɛsishɔn injinɛri.

-

Anti Vibration Pads Ridyus di nɔys we dɛn de mek na di ikwipmɛnt fayn fayn wan .2025年7月28日Anti Vibration Pads Ridyus di nɔys we dɛn de mek na di ikwipmɛnt fayn fayn wan .

Anti Vibration Pads Ridyus di nɔys we dɛn de mek na di ikwipmɛnt fayn fayn wan .2025年7月28日Anti Vibration Pads Ridyus di nɔys we dɛn de mek na di ikwipmɛnt fayn fayn wan . -

-

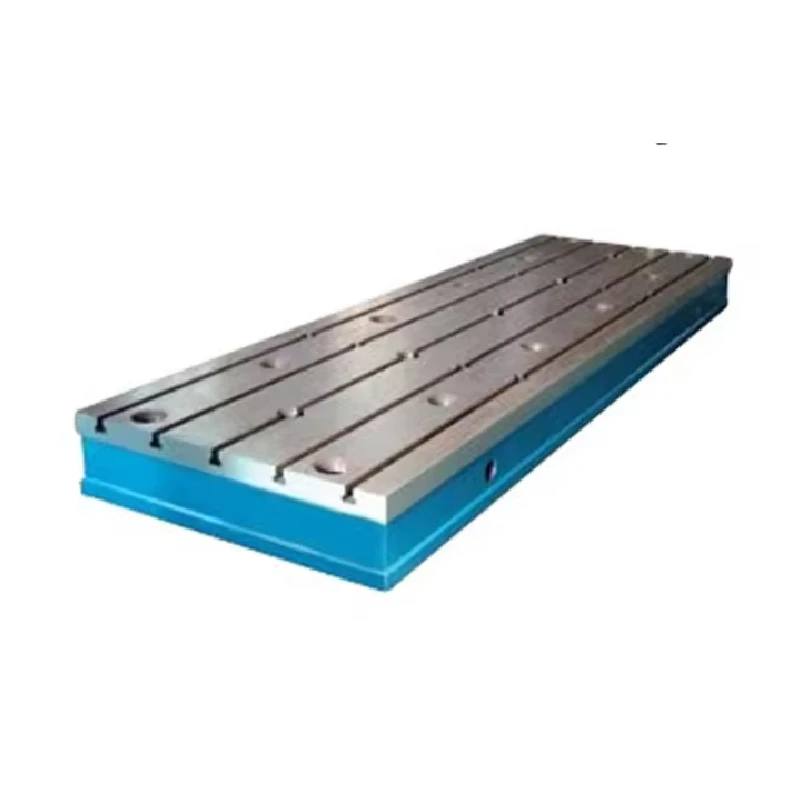

Kast ayɛn sɔfayz plet aerospace inspekshɔn .2025年7月28日Kast ayɛn sɔfayz plet aerospace inspekshɔn .

Kast ayɛn sɔfayz plet aerospace inspekshɔn .2025年7月28日Kast ayɛn sɔfayz plet aerospace inspekshɔn .