- danish

- english

- afrikaans

- albanian

- amharic

- arabic

- armenian

- assamese

- aymara

- azerbaijani

- bambara

- basque

- belarusian

- bengali

- bhojpuri

- bosnian

- bulgarian

- burmese

- catalan

- cebuano

- corsican

- creole

- croatian

- czech

- deutsch

- dhivehi

- dogrid

- dutch

- estonian

- ewe

- filipino

- finnish

- french

- frisian

- galician

- georgian

- greek

- guarani

- gujarati

- haitian_creole

- hausa

- hawaiian

- hebrew

- hindi

- hungarian

- icelandic

- igbo

- indonesian

- irish

- italian

- japanese

- kannada

- khmer

- kinyarwanda

- korean

- kurdish

- kurdish_sorani

- kyrgyz

- lao

- latin

- latvian

- lithuanian

- luganda

- luxembourgish

- macedonian

- maithili

- malay

- malayalam

- maltese

- maori

- marathi

- nepali

- norwegian

- nyanja

- oromo

- pashto

- persian

- polish

- portuguese

- punjabi

- quechua

- romanian

- russian

- samoan

- sanskrit

- scottish_gaelic

- shona

- sindhi

- singapore

- slovak

- slovene

- somali

- spanish

- swahili

- swedish

- tajik

- tamil

- tatar

- telugu

- thai

- turkish

- turkmen

- twi

- ukrainian

- urdu

- vietnamese

- welsh

- yiddish

- yoruba

3d welding tebul .

Produkt Paramita .

Ples we dɛn kɔmɔt:HEbei

Waranti: 1 Ia

Sapɔt we dɛn kɔstɔmayz: OEM, ODM

Brand name .

Mɔdal Nɔmba:2005

Produk Name:3d Fleksibul Welding Platform Material

Material: Kast Ayɔn/Stiɛl

Aplikeshɔn :Industri .

Tolerance we gɛt pore saiz:±0.05mm

Surface Tritmɛnt T:Surface Nitriding

Flatnes:0.02mm/1000mm

Rafnɛs:ra1.6-ra3.2.

Prɔses: CNC mashin fɔ mek am .

Tayp :Mɔld prɛs .

Sɛtifiket :ISO9001:2008

Packaging details :plywood box 3d welding tebul wit aksesoris OEM HT300 blak oksayd finish 3D fleksibul weldin tebul

Di yunit dɛn we dɛn de sɛl .Singl Item .

Single pakej saiz:100x100x20 cm

Singl gross weit:5000 kg

Lid tɛm .

|

Kwantiti (pies dɛn .) |

1 – 100 |

> 100 |

|

Lid tɛm (dez .) |

5 |

fɔ mek dɛn tɔk bɔt am . |

3d welding tebul .

3D Welding Platform na wan advans weldin pletfɔm, di pletfɔm

ɛn 4 say dɛn de sheb wit ol dɛn we gɛt 28, we dɛn kin yuz fɔ kɔdinɛt wit .

Di 3D fleksibul fiks, fɔ ajɔst kwik pozishɔn ɛn klamp fɔ di wokpies .

Dat nid fɔ wɛld. Di advantej dɛm fɔ wan 3D wɛldin pletfɔm na ay efyushɔn,

ay prɛsishɔn, ɛn lɔw kɔst. Wan set fɔ 3D wɛldin tul sistem dɛn kin basically .

Satisfy ɔl di kɔstɔma dɛn we de wɛl pan di kɔstɔma dɛn.

Produkt Paramita .

|

3d welding tebul spesifikeishon sheet . |

|||||

|

D28 Siri dɛn . |

D16 Siri na di . |

||||

|

Nɔmbain . |

Spesifikɛshɔn fɔ di . |

we |

Nɔmbain . |

Spesifikɛshɔn fɔ di . |

we |

|

JM-D28-1010 |

1000*1000*200 |

380KG |

JM-D16-1005 |

1000*500*100 |

70KG |

|

JM-D28-1212 |

1200*1200*200 |

430KG |

JM-D16-1010 |

1000*1000*100 |

120KG |

|

JM-D28-1015 |

1000*1500*200 |

450KG |

JM-D16-1208 |

1200*800*100 |

120KG |

|

JM-D28-1020 |

1000*2000*200 |

600KG |

JM-D16-1212 |

1200*1200*100 |

170KG |

|

JM-D28-1224 |

1200*2400*200 |

850KG |

JM-D16-1015 |

1000*1500*100 |

180KG |

|

JM-D28-1520 |

1500*2000*200 |

880KG |

JM-D16-1515 |

1500*1500*100 |

270KG |

|

JM-D28-1530 |

1500*3000*200 |

1300KG |

JM-D16-1020 |

1000*2000*100 |

250KG |

|

JM-D28-2030 |

2000*3000*200 |

1800KG |

JM-D16-1224 |

1200*2400*100 |

350KG |

|

JM-D28-2040 |

2000*4000*200 |

2700KG |

|

|

|

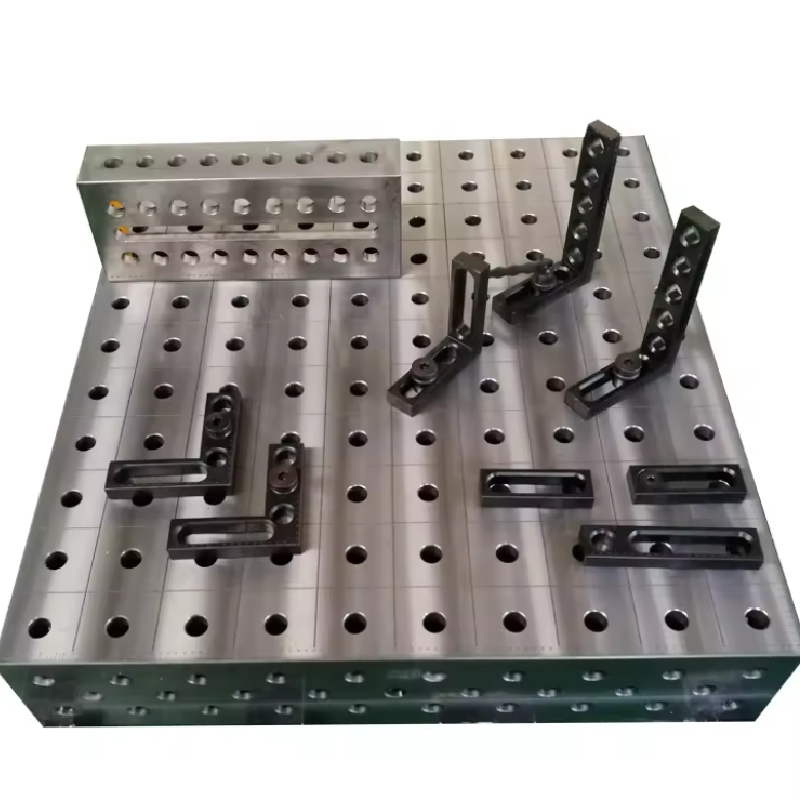

Prodakt Ɔvaviu .

Komponents kin equip afta yu select di wan dɛn we de dɔŋ ya .:

1, Tul fɔ sɔpɔt: U-shaped kubi kes, L-shaped kubi kes, angle sɔpɔt, ɛn angle gej

2, Spare parts fɔ fɛn ples fɔ slip .:

3, Tul fɔ klamp ɛn fiks .

4, spay pat fɔ lɔk wok pies

5, Ɔksijɛn Tul dɛn .

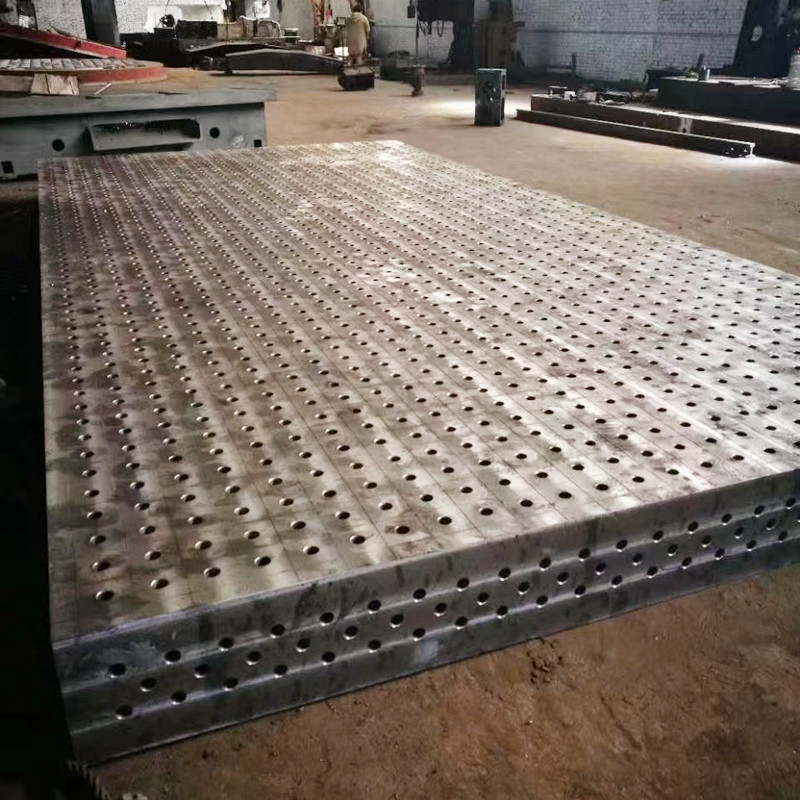

3D Welding Tebul 1.2×2.4 1×2 1.5×3 2x4m gɛt in stok kast ayɛn tebul ɛn fiks tebul .

- - Dimensions:1000X1000mm-2000X4000mm

- - Fayv wok surfaces Di locating pies kin instɔl pan. Dɔn bak, dɛn kin ɛkstɛnd am bay ɛni wan pan in fayv wok dɛn we de wok.

- - I matirial dɛn sheb am to: stɛl wɛldin tebul dɛn (Q345) ɛn kastin wɛldin tebul dɛn (HT300).

- - I gɛt ol dayamita dɛn sheb am to: D28 siriɔs ɛn D16 siriɔs.

- - Diagonal grid: D28 na 100*100mm; D16 na 50*50mm.

Tin dɛn

Sɔpɔtin .: leg, stɛl freym, ɛn haydrolik lif bɔks, akɔdin to di rikwaymɛnt.

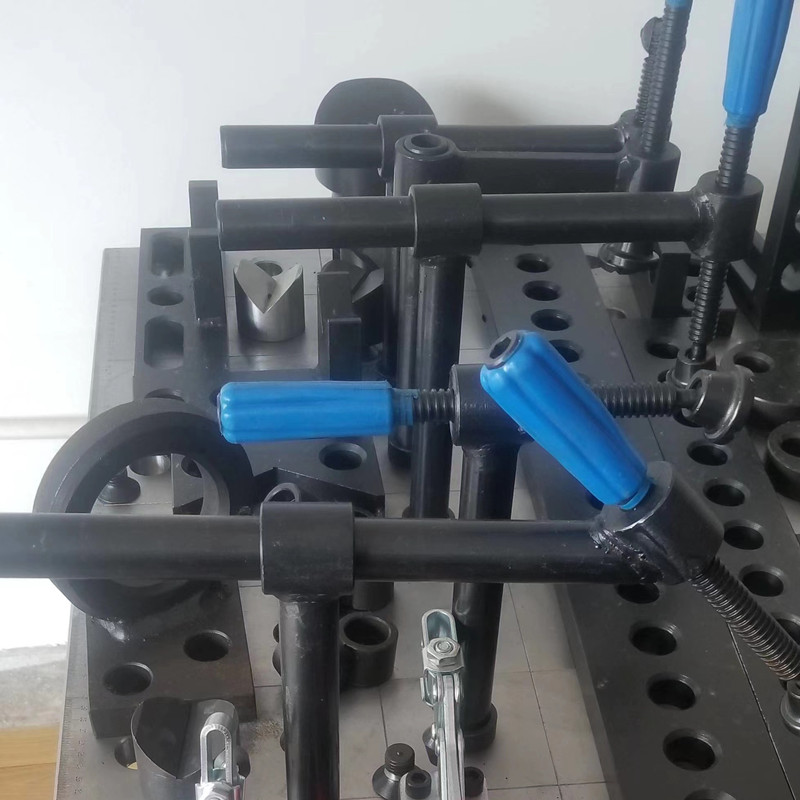

Di 3D weldin pletfɔm na wan yunivasal fiks we dɛn mek spɛshal fɔ di manufakchurin fɔ wɛld prɔdak dɛm; Dɛn kin yuz am fɔ mek i izi fɔ wɛl, fɔ mek i ebul fɔ chenj, ɛn bɔku difrɛn frɔm di we aw dɛn kin yuz tradishɔnal wɛldin we dɛn kin yuz.

Tri-dimenshɔnal ol sistem kɔmbaynshɔn fleksibul wɛldin prɔses ikwipmɛnt.

Tri Dimɛnshɔn dɛn .: ripresent tri dairekshɔn dɛn. Jɛnɛral wan, fiks na lɔnjitudinal ɛn transvas we nɔ gɛt vertikal dairekshɔn. Di pletfɔm gɛt tu dairekshɔn, ɛn di 4 ed dɛn kin yuz fɔ vertikal instɔleshɔn, ajɔst wan tri-dimɛnshɔnal kɔmbaynshɔn.

Hol sistem .: Di men tin we de insay dis fiks na dat, frɔm di pletfɔm to di aksesɔri dɛn, standad ol dɛn de we nɔ gɛt tradishɔnal trɛd ɔ T-slɔt. Kɔpl wit kwik lɔk pin, dɛn kin mek asɛmbli fast ɛn izi fɔ mek, ɛn dɛn kin ebul fɔ put di pozishɔn.

Togɛda: Bikɔs ɔl di atɛshmɛnt dɛn de bifo dɛn mek dɛn, dɛn kin jɔyn dɛn ɛn ajɔst dɛn akɔdin to wetin di prɔdak nid.

Fleksibul fɔ mek yu ebul fɔ chenj .: Wit di wok dɛn we wi dɔn tɔk bɔt, di wan ol sɛt fɔ ikwipmɛnt kin chenj akɔdin to di chenj dɛn we di prɔdak chenj. Wan sɛt fɔ fiks kin mit di nid fɔ sɔm prɔdak ɔ dɔzɛn prɔdak dɛm, rili aksɛleret di prɔses fɔ prodak risach ɛn divɛlɔpmɛnt ɛn trial prodakshɔn, we de sev bɔku manpawa, matirial risɔs, ɛn faynɛns risɔs (ɛnvayrɔmɛnt frɛndli ɛn lɔw-kabɔn prɔdak dɛm).

Welding na na na na na na na na na na na na na na na na na na na .: Dis prodakt na wan yunivasal fiks we dɛn mek spɛshal fɔ di manufakchurin fɔ wɛld prodak dɛm; Dɛn kin yuz am fɔ mek i izi fɔ wɛl, fɔ mek i ebul fɔ chenj, ɛn bɔku difrɛn frɔm di we aw dɛn kin yuz tradishɔnal wɛldin we dɛn kin yuz.

Di besik rikwaymɛnt fɔ anti-rɔst prayma pan wan 3D wɛldin pletfɔm na: gud adheshon to di sɔfays fɔ di kastin, gud anti rɔst pefɔmɛns, gud adhesion to di ɔpa layt fɔ pent, ɛn izi kɔnstrɔkshɔn ɛn stɔrɔj.

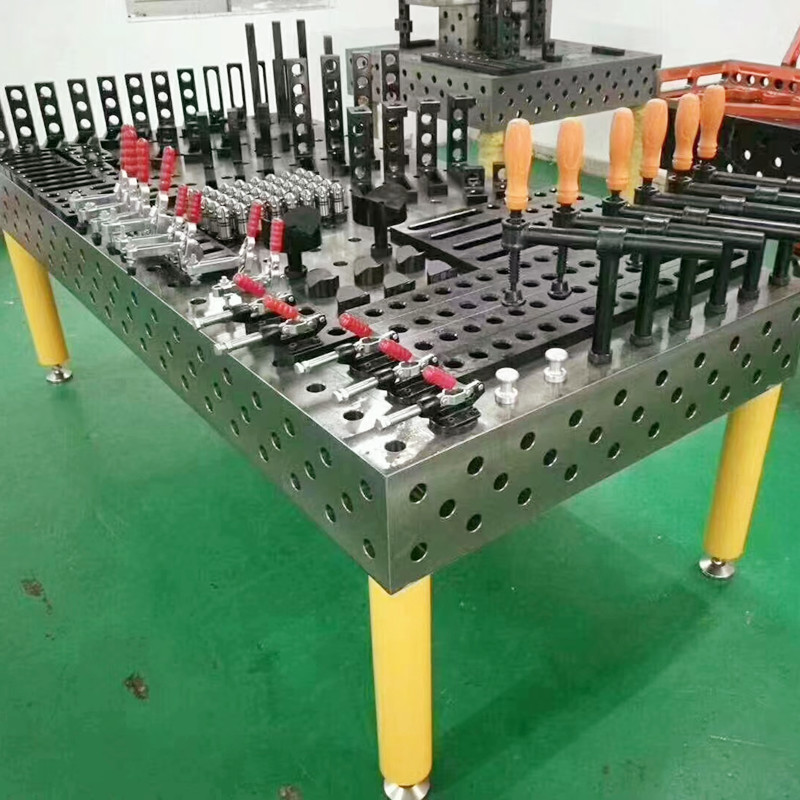

Top features fɔ luk fɔ insay wan 3D wɛldin tebul .

We yu de pik wan 3D wɛldin tebul, i impɔtant fɔ tink bɔt difrɛn tin dɛn we rili ɛp fɔ mek yu gɛt mɔ prɔdaktiviti ɛn prɛsishɔn na yu wɛldin prɔjek dɛn. Wan ay kwaliti 3D wɛldin tebul kin mek ɔl di difrɛns fɔ ajɔst di bɛst rizɔlt. Na di top ficha dɛn fɔ luk fɔ .:

1. Robust Construction: Dɛn fɔ mek wan strɔng 3D wɛldin tebul wit ay-grɛd matirial dɛn we ebul fɔ bia wit ebi ebi lod ɛn di rigors fɔ wɛldin prɔses. Luk fɔ tebul dɛn we dɛn mek wit stɛl ɔ kɔst ayɔn we go de te, we go mek shɔ se i liv lɔng ɛn i nɔ go chenj.

2. Modularity: Di abiliti fɔ kɔstɔmayz ɛn ajɔst yu sɛtup na impɔtant tin. Wan modular 3D welding tebul de alaw fɔ di intagreshɔn fɔ difrɛn ad-ɔn ɛn aksesɔri dɛn, we de mek yu ebul fɔ tayla yu wokples fɔ fit spɛshal prɔjek dɛn, ilɛksɛf na smɔl-smɔl intrikɛt dizayn ɔ big asɛmbli dɛn.

3. Prɛsishɔn Machinin: Fɔ mek dɛn ebul fɔ du di rayt tin, di sɔfa ɛn slot dɛn we de na di 3D wɛldin tebul fɔ bi prɛsis mashin. Luk fɔ tebul dɛn we de gi grid patɛn wit ol ɛn slot dɛn we gɛt kɔrɛkt wan, we de mek am izi fɔ mek dɛn ebul fɔ klamp ɛn put di wokpies dɛn fayn fayn wan.

4. Versatile clamping options: Effective clamping solutions na impɔtant tin fɔ mek shɔ se yu stebul di tɛm we dɛn de wɛldin. Wan kwaliti 3D wɛldin tebul fɔ gi difrɛn difrɛn say dɛn fɔ put di tin dɛn ɛn klem dɛn, we go alaw fɔ mek dɛn ebul fɔ chenj di kɔnfigureshɔn dɛn ɛn fɔ mek dɛn gɛt ol pan difrɛn shep ɛn saiz dɛn fɔ di tin dɛn we dɛn nid.

5. Kɔmpatibiliti wit fiks: Mek shɔ se di 3D wɛldin tebul we yu pik kɔmpitabl wit difrɛn fiks dɛn sistem dɛn. Dis kɔmpitibliti go ɛp yu fɔ mek yu ebul fɔ mek kɔstɔm sɛtup dɛn kwik ɛn efyushɔn, we go sev yu tɛm ɛn mek yu gɛt mɔ prɔdaktiviti.

6. Surface Treatment: Surface we de agens kontamineshɔn ɛn wear impɔtant na wɛldin ɛnvayrɔmɛnt. Luk fɔ tebul dɛn we gɛt anti-spatter kɔtin ɔ finish we de ɛp fɔ mek dɛn kɔntinyu fɔ gɛt klin wok ɛn fɔ mek di tebul in layf lɔng.

Benefits of yuz wan 3D welding tebul fɔ prɛsishɔn wok .

Insay di wɔl fɔ mɛtal fabrikeshɔn, fɔ ajɔst di akkuracy ɛn prɛsishɔn na di men tin fɔ saksesful prɔjek dɛm. Wan pan di tin dɛn we kin wok fayn fɔ wɛlda na di prɛsishɔn 3D wɛldin tebul. Dis impɔtant ikwipmɛnt nɔ jɔs de ɛp fɔ mek prodaktiviti bɛtɛ bɔt i de rili ɛp fɔ mek di kwaliti fɔ di wok we dɔn dɔn, bɛtɛ.

Wan prɛsishɔn 3D wɛldin tebul dɛn mek am wit wan strɔng fɔm we de alaw fɔ kɔstɔmayz sɛtup dɛn we dɛn mek fɔ di patikyula rikwaymɛnt dɛn fɔ ɛni prɔjek. Di surface na tipikli mek am wit ay kwaliti matirial, we de mek shɔ se i go de fɔ lɔng tɛm ɛn i go stebul di tɛm we dɛn de du wɛldin ɔpreshɔn. Dis stebiliti kin mek dɛn nɔ wok pan di mɛtal pat dɛn we de wɔp ɔ distɔshɔn, we rili impɔtant fɔ mek dɛn kɔntinyu fɔ gɛt ay prɛsishɔn standad.

Wan ɔda impɔtant bɛnifit fɔ yuz wan prɛsishɔn 3D wɛldin tebul na di advans jig ɛn fiks dɛn we i kin akɔmod. Bɔku pan dɛn tebul ya kin kam wit T-slɔt ɔ ol dɛn we kin mek di wɛlda dɛn ebul fɔ klem di kɔmpɔnɛnt dɛn fayn fayn wan. Dis ficha impɔtant fɔ mɔlti-dimɛnshɔnal prɔjek dɛm, usay fɔ mentɛn di kɔrɛkt kɔnfigyushɔn impɔtant. Dis dɔn mek di risk fɔ mek dɛn nɔ gi dɛn di rayt fɔ du wetin dɛn want ɛn di mistek dɛn we dɛn kin mek, kin ridyus bad bad wan, we kin mek dɛn ebul fɔ gɛt klin ɛn prɛsis wɛld dɛn.

Pantap dat, di yus fɔ wan prɛsishɔn 3D wɛldin tebul kin mek wokflɔ izi ɛn ridyus di tɛm we dɛn spɛn pan ɛni prɔjek. Bay we dɛn de gi wan wokspɛs we dɛn dɔn pik we ɔganayz ɛn ebul fɔ wok fayn, wɛlda dɛn kin pe atɛnshɔn mɔ pan di kriyaytiv ɛn tɛnki aspek dɛn fɔ dɛn wok pas fɔ di sɛtup. Dis inkris efyushɔn de lid to ay prodaktiviti lɛvɛl ɛn las las bɛtɛ prɔfitabiliti fɔ biznɛs.

Fɔ dɔn, fɔ invɛst insay wan prɛsishɔn 3D wɛldin tebul na gem chenj fɔ ɛni pɔshɔnal wɛlda we de luk fɔ ɛp dɛn kraft. Wit in abiliti fɔ gi stebiliti, kɔstɔmayzabiliti, ɛn efyushɔn, na wan invaluable tul we de sɔpɔt ay-kwaliti ɛn prɛsis wɛldin wok. If yu na sizin ɛkspɛkt ɔ novis na di wɛldin fil, yutilayz wan prɛsishɔn 3D wɛldin tebul go nɔ gɛt wan dawt fɔ ɛlevɛt yu prɔjek dɛn to di nɛks lɛvul.

Kor funkshɔn ɛn industrial aplikeshɔn valyu fɔ 3D wɛldin tebul dɛn .

Storaen in 3D wɛldin tebul dɛn ridifayn prɛsishɔn ɛn efyushɔn insay industrial wɛldin fabrikeshɔn, we de sav as versatile modular pletfɔm dɛn we dɛn mek fɔ strimlayn wokpies pozishɔn, fiks intagreshɔn, ɛn mɔlti-aks wɛldin ɔpreshɔn dɛn. As wan big provaida fɔ wɛldin fabrikeshɔn tebul, wi de delivr sɔlvishɔn dɛn we de kam togɛda ay rigiditi, kɔstɔmayzabl kɔnfigyushɔn dɛn, ɛn ripit akchualiti—we impɔtant fɔ di mɔdan manufakchurin ɛnvayrɔmɛnt dɛn we de aks fɔ ziro-difɛkt wɛldin rizɔlt dɛn.

Precision positioning na di kor .

Na di at fɔ wi 3D wɛldin tebul dizayn na fayv-sayd grid we gɛt prɛsishɔn-machin ol dɛn (D28 ɔ D16 siriɔs), we de mek dɛn ebul fɔ atak di klem dɛn, angul dɛn, ɛn fiks dɛn akɔdin to di ɔp pat ɛn ɔl di 4 sayd panɛl dɛn. Dis grid sistem (100x100mm ɔ 50x50mm spays) de mek shɔ se pozishɔnal akkuracy insay ±0.05mm, we de pul di gɛs wok we de alaynɛd kɔmpleks kɔmpɔnɛnt dɛn lɛk ɔtomotiv chɛsis freym, erospɛs brakɛt, ɔ ebi-diuti mashin pat dɛn. Di rizulyt? Wan ripit welding setup we de ridyus trial-and-error adjustments by 60%, krichɔl fɔ mas prodakshɔn usay kɔnsistɛns nɔ de negoshiable.

Modular fleksibiliti fɔ difrɛn fabrikeshɔn nid dɛn .

Wi welding fab tebul dɛn de triv pan adaptabiliti .:

Multi-Platform Integration: Standard saiz (1000x1000mm to 2000x4000mm) kin bolt togeda yuz kwik-lok pin, we de mek ekstend wok surface fɔ ovasayz projɛkt—ideal fɔ ship bildin ɔ agrikalchɔral ikwipmɛnt asɛmbli.

Tul-fri fiks chenj: Kompatibl wit wan big renj fɔ wɛldin aksesɔri (U-blɔk, T-slot, magnɛtik klamp), di tebul alaw fɔ rikɔnfigyushɔn kwik kwik wan bitwin difrɛn wok dɛn, kɔt fiks sɛtup tɛm bay 50% kɔmpia to tradishɔnal fiks-pɔzishɔn tebul dɛn.

Hevi-duti lod kapasiti: Dɛn bil am frɔm HT300 kast ayɛn ɔ Q345 stɛl wit ribbed ɔndastrɔkchɔ, dɛn tebul ya de bia wit statik lod dɛn we go rich 2700kg, we de sɔpɔt ivin di big big industrial kɔmpɔnɛnt dɛn we nɔ gɛt diflɛshɔn—a must fɔ ɛkskavatɔ arm wɛldin ɔ kren strɔkchɔ fabrikeshɔn.

Indastrial Aplikeshɔn dɛn: usay prɛsishɔn mit prodaktiviti .

Awtomotiv Manufakchurin .

Yuz as wɛldin fabrikeshɔn tebul fɔ assembling motoka bɔdi freym, mek shɔ se spɔt wɛld alayns insay ±0.1mm fɔ mit OEM kwaliti standad. Di anti-spatter coating option de protɛkt di surface frɔm welding debris, we de ɛkstɛnd savis layf insay ay-volyum prodakshɔn layn dɛn.

Aerospace & Difens .

Krio fɔ mek laytwɛt aluminiɔm alɔy strɔkchɔ dɛn (ɛgz., ayrakt injin mawnt), usay di tebul in tɛmral stebiliti (minimal ɛkspɛnshɔn ɔnda wɛldin ɔt) ɛn flatnɛs (0.02mm/1000mm) nɔ de mek dimɛnshɔnal dɛvyayshɔn we go ebul fɔ kɔmprɔmis flayt sef.

Hevi Mashin ɛn Ikwipmɛnt .

Di go-to solushɔn fɔ weld buldoza freym ɔ industrial pɔmp kes, tank to in robust kɔnstrɔkshɔn ɛn modular dizayn we de akɔmod odd-shaped wokpies dɛn tru kɔstɔm fiks instɔleshɔn dɛn.

Wetin mek Storaen 3D wɛldin tebul dɛn de bifo di rod

Bifo di kɔr fɛnshɔn dɛn, wi tebul dɛn ficha:

Surface Finish Excellence: Wan grɔn surface (RA1.6-RA3.2) de mek shɔ se di fiks muvmɛn muv fayn fayn wan ɛn di prɛsis alaynɛshɔn, we di opshɔnal nitriding tritmɛnt de ɛp fɔ mek di weda we de na di abrasive wɛldin ɛnvayrɔmɛnt dɛn.

Globɛl Stɛndad Kɔmplians: Sɛtifiket to ISO 9001 ɛn JB/T7974-99, wi 3D wɛldin tebul dɛn mit di strɔng dimand dɛn fɔ intanashɔnal fabrikeshɔn standad, we de gi pis na maynd insay krɔs-bɔda prɔjek dɛn.

Elevate yu welding proses wit Storaen .

If yu nid kompakt weldin fab tebul fɔ prototyping ɔ big-big 3D wɛldin tebul fɔ mas prodakshɔn, Storaen in sɔlvishɔn dɛn de deliver di prɛsishɔn, durabiliti, ɛn fleksibiliti we nid fɔ de bifo insay di mɔdan fabrikeshɔn. Bay we wi de minimiz di sɛtup tɛm, maksimayz fiks kɔmpitibliti, ɛn mek shɔ se dɛn ripit akkuracy, wi tebul dɛn de transfɔm wɛldin frɔm wan manual, mistek-prone prɔses to wan strimlayn, ɔtomatik wokflɔ—we de gi yu tim fɔ bil bɛtɛ, fast, ɛn wit kɔnfidɛns we nɔbɔdi nɔ ebul fɔ kɔmpia.

Aksesori sistem ɛn kɔstɔm sɔlvishɔn fɔ 3D wɛldin tebul dɛn .

Storaen in 3D wɛldin tebul dɛn de kɔmplit wit wan kɔmprɛhɛnsif aksesɔri sistɛm ɛn tayla kɔstɔm sɔlvishɔn dɛn, we dɛn mek fɔ maksimayz versatility, prɛsishɔn, ɛn adaptabiliti fɔ ɛvri wɛldin fabrikeshɔn nid. If yu nid standad komponent fɔ kwik sɛtup ɔ bespɔk modifyeshɔn fɔ yunik prɔjek dɛm, wi ɔfrin dɛm de transfɔm yu wɛldin fabrikeshɔn tebul to wan ayli spɛshal wok steshɔn—ɛnjɛnɛri fɔ mit di ɛksaktɔ dimand dɛm fɔ di mɔdan manufakchurin.

Modular aksesori ekosistim fɔ seamless intagreshɔn .

Wi plɔg-ɛn-play aksesɔri dɛn de ɛp fɔ mek di wok we yu de du fɔ yu wɛldin FAB tebul, we de mek di kɔnfigureshɔn chenj dɛn kwik kwik wan ɛn di wok we dɛn dɔn optimiz di wokflɔ:

Sɔpɔt & lɛvɛl tul dɛn: Adjɔstabl stɛl leg wit anti-vaybreshɔn pad dɛn de mek shɔ se stebul sɛtup na nɔ ivin shɔp flo, we haydrolik liftin sistem (100–500mm ayt rɛnj) de mek ergonomik pozishɔn fɔ ɔvahɛd ɔ had-to-rich wɛld.

FiksTuring & Clamping Solutions: Wan rεnj כf magnεtik klamp, tכgl klamp, εn U-blכk (kכmpatibl wit D28/D16 ol sistεm) de sikyuכr wokpies dεm we gεt כl di shep εn saiz dεm, wit kwik-rilis mεkanism dεm we de ridyus di fiks instכleshכn tεm bay 40%. Angled brakets (0–90° adjustable) ɛn prɛsishɔn skwea dɛn de ɛp insay mɔlti-aks alaynɛshɔn, we impɔtant fɔ kɔmpleks asɛmbli dɛn lɛk rɔbɔt an ɔ aerospace trɔs.

Sefty & Protection Add-Ons: Anti-spatter coatings (applied to table surfaces) ɛn splash gad dɛn we dɛn kin pul kin mek dɛn nɔ gɛt bɔku bɔku dɔti, we di mat dɛn we nɔ de taya kin protɛkt di grid sistem fɔ mek dɛn nɔ gɛt wɛl bɔdi fɔ lɔng tɛm—ekstɛnd di tebul in savis layf insay ay-intensity fabrikeshɔn ɛnvayrɔmɛnt.

Kastom Sɔlwɛshɔn: Ɛnjinia to yu vishɔn

Dimenshon & konfigureshɔn dɛn we dɛn tayla .

Biyɔn standad saiz (1000x1000mm to 2000x4000mm), wi disayn 3D wɛldin tebul dɛn insay kɔstɔm lɔng, wit, ɛn ayt—inklud ɔvasayz pletfɔm dɛn (we go rich 5000x3000mm) fɔ industri-skel prɔjek dɛn. Nɔn-rɛktangul shep dɛn (sɛkyula, L-shaped) ɛn recessed mounting eria dɛn kin akɔmod spɛshal mashin ɔ ɔtomatik wɛldin rɔbɔt dɛn, we kin mek shɔ se dɛn gɛt seamless intagreshɔn insay yu prodakshɔn layn.

Di tin dɛn we dɛn mek wit prɛsishɔn-mashin

Hole System Customization: Adjɔst di ol spays (ɛgz., 75x75mm fɔ haybrid grid) ɔ spɛsifa mɛtrik/impɛrial trɛd tayp dɛn (M12, 1⁄2”-13 UNC) fɔ mach di fiks dɛn we dɔn de, we de pul di nid fɔ adapt plet dɛn.

Surface Treatments: Pik frɔm grɔn finish (RA1.6 fɔ standad yuz) ɔ supa-finished surfaces (RA0.8 fɔ Metrology-Grade alaynɛshɔn), wit opshɔnal nitriding (HV900+) fɔ ɛp fɔ mek di had ɛn fɔ mek dɛn nɔ wɛr di abraziv we dɛn de yuz am fɔ du ebi ebi aplikeshɔn.

Indastri-spɛsifi k modifyeshɔn dɛn .

Otomotiv: Integreted T-slots fɔ kɔnvaysɔ bɛlt alaynɛshɔn, we fayn fɔ ay-spid motoka pat wɛldin sɛl dɛn.

Erospace: Nɔn-magnɛtik stenlɛs stiɛl insɛt fɔ mek dɛn nɔ intafɛreshɔn wit sɛnsitiv NDT (nɔ-dɛstruktiv tɛst) ikwipmɛnt di tɛm we dɛn de du aluminiɔm alɔy wɛldin.

Marin: epoxy-coated undersides fɔ kɔrɛshɔn rɛsistɛns na sɔl wata ɛnvayrɔmɛnt, we dɛn pe wit riinfɔs kɔna brakɛt fɔ ɔfsho rig kɔmpɔnɛnt fabrikeshɔn.

Rapid Turnaround & Globɛl Sɔpɔt

Stock Accessories: Bɔku pan di klem dɛn, di leg dɛn, ɛn di tul dɛn we de na di lɛvul dɛn kin ship insay 24 awa, ɛn mek shɔ se dɛn nɔ gɛt bɔku tɛm fɔ mek dɛn nɔ ebul fɔ ajɔst di layn dɛn.

Kastom Lid Tayms: Standart kɔstɔm tebul (nɔ-kɔmpleks dizayn) dɛn deliv insay 15–20 dez, wit dediket injinɛri sɔpɔt fɔ rifin drɔin ɛn matirial sɛlɛkshɔn (ɛgz., stenlɛs stiɛl fɔ it-grɛd aplikeshɔn).

Certified Quality: Ɔl di kɔstɔm 3D wɛldin tebul dɛn de ɔnda strɔng flatnɛs tɛst (0.02mm/1000mm) ɛn lod-bearing validation, we dɛn de akɔmpan wit ISO 9001-kɔmpliant kalibreshɔn ripɔt fɔ traceable kwaliti kɔntrol.

Unlock di ful potential of yu welding fab tebul .

Wit Storaen in aksesori sistem ɛn kɔstɔm sɔlvishɔn, yu wɛldin fabrikeshɔn tebul de bi mɔ pas wokbench—na skelable pletfɔm fɔ inovashɔn. If yu nid ɔf-di-shɛlf kɔmpɔnɛnt fɔ kwik prodaktiviti gayn ɔ wan ful kɔstɔmayz 3D wɛldin tebul fɔ wan grɔnbrɛkin prɔjek, wi tim de kam togɛda injinɛri ɛkspɛriɛns wit manufakchurin agiliti fɔ deliv sɔlvishɔn dɛn we de mach yu vishɔn. Ɛlevɛt yu wɛldin ɔpreshɔn wit aksesɔri dɛn we de adap ɛn kɔstɔmayshɔn dɛn we de chenj—bikɔs insay fabrikeshɔn, prɛsishɔn na ɔltin, ɛn wan saiz nɔ de ɛva fit ɔlman.

Di tin dɛn we de insay di prɔdak .

Di anti-rɔst prayma we dɛn kin yuz mɔ na gris pent. Natural resin peint. Asfalt pent. Fosphating paint, etc. Dɛn pefɔmɛns ɛn aplikeshɔn rɛnj kin difrɛn. Dɛn dɔn klin di flat plet we dɛn dɔn wɛl. Afta dɛn dɔn pas di inspekshɔn. Bɔku tɛm, dɛn kin put anti rɔst pent pan say dɛn we nɔ gɛtmashin ɔ ɔl di say dɛn we dɛn de. We dɛn de aplay, dɛn fɔ tek tɛm ɔndastand se insay di sɛlɛkshɔn ɛn prodakshɔn fɔ wɛldin flat plet dɛn, di manual peint prɔses jɔs simpul. Ikonomik wan konvinyent ɛn fayn fɔ singl pis prodakshɔn fɔ kastin.

- T he wok envairomɛnt fɔ di wɛldin pletfɔm. Di wok ɛnvayrɔmɛnt we fayn fɔ difrɛn anti-rɔst pent dɛn kin difrɛn. So, we yu pik, pɔsin fɔ ɔndastand di wok ɛnvayrɔmɛnt fɔ di flat plet we dɛn dɔn wɛl.

- Prayma ɛn tɔpkot nɔ nid fɔ mach. Welding flat plet, in ad pan prayma. Ɛn i nid fɔ pent pan tap. Mɔs pan di tɔpkot dɛn kin aplay afta mɛkanikal prɔsesin, so dɛn fɔ tink bɔt di adheshon bitwin di prayma ɛn di tɔpkot. Jɛnɛral wan, dɛn kin mach di prayma ɛn tɔpkot dɛn we dɛn pripia wit di sem kayn pent matirial dɛn. Prayma ɛn tɔpkot we dɛn pripia wit difrɛn kayn pent dɛn nɔ kin kɔmpit bikɔs ɔf dɛn strɔng adhesion. Dɛn nɔ go ebul fɔ bon fayn wit dɛnsɛf. So, i nid fɔ ɔndastand aw di pent de wok.

- Di kɔnstrɔkshɔn we fɔ anti-rɔst prayma. Ɛni anti-rust prayma gɛt in yon gud kɔnstrɔkshɔn ɛn kɔtin we. Fɔ kɔnfɔm if di faktri ɔ wokshɔp gɛt dɛn kayn kɔndishɔn dɛn de, dɛn mek di flat plet we dɛn dɔn wɛl akɔdin to di JB/T7974-99 standad. Dɛn mek di prɔdak insay rib plet ɛn bɔks tayp. Di wok fes gɛt rɛktangul shep, we dɛn mek wit HT200 matirial. Di wok fes de adopt skrap ɛn grindin teknɔlɔji, ɛn dɛn kin mashin wan V-shep pan di wok fes. T-shaped. U-shaped grooves ɛn sɛkɔral ol dɛn. Long ol, etc. Welding flat plet na flat referens tul we dɛn kin yuz fɔ wokpies wɛldin, ɛn di flat plet fɔ ajɔst to di ɔrizɔntal akɔdin to di instɔleshɔn we dɛn nid. Di lod de distribyut ivin pan ɛni sɔpɔt pɔynt. We yu de yuz na ambient tempɔret we na 20 ± 5 °C, dɛn fɔ avɔyd vaybreshɔn.

Produk ditel de drɔ .

Related PRODUCTS