- danish

- english

- afrikaans

- albanian

- amharic

- arabic

- armenian

- assamese

- aymara

- azerbaijani

- bambara

- basque

- belarusian

- bengali

- bhojpuri

- bosnian

- bulgarian

- burmese

- catalan

- cebuano

- corsican

- creole

- croatian

- czech

- deutsch

- dhivehi

- dogrid

- dutch

- estonian

- ewe

- filipino

- finnish

- french

- frisian

- galician

- georgian

- greek

- guarani

- gujarati

- haitian_creole

- hausa

- hawaiian

- hebrew

- hindi

- hungarian

- icelandic

- igbo

- indonesian

- irish

- italian

- japanese

- kannada

- khmer

- kinyarwanda

- korean

- kurdish

- kurdish_sorani

- kyrgyz

- lao

- latin

- latvian

- lithuanian

- luganda

- luxembourgish

- macedonian

- maithili

- malay

- malayalam

- maltese

- maori

- marathi

- nepali

- norwegian

- nyanja

- oromo

- pashto

- persian

- polish

- portuguese

- punjabi

- quechua

- romanian

- russian

- samoan

- sanskrit

- scottish_gaelic

- shona

- sindhi

- singapore

- slovak

- slovene

- somali

- spanish

- swahili

- swedish

- tajik

- tamil

- tatar

- telugu

- thai

- turkish

- turkmen

- twi

- ukrainian

- urdu

- vietnamese

- welsh

- yiddish

- yoruba

Bar Lɛvul .

Di diskripshɔn fɔ di prɔdak .

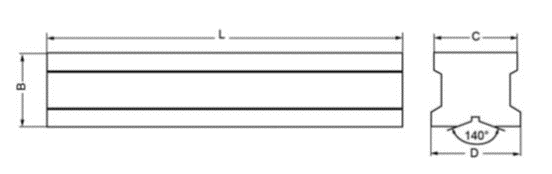

- - Adjustable Main Vial 0,0002"/10."

- - V-grooved bays.

- - wit krɔs tɛst vayl.

- - Robust cast ayɛn bɔdi.

- - We yu kɔmpia am to rɛgyula masta prɛsishɔn lɛvɛl, dis lɛvɛl na dizayn ɛn prodyuz insay wan mɔ sofistikiet ɛnvayrɔmɛnt.

- Prodakt Points ɛn Aplikeshɔn fɔ Bar Lɛvɛl:Prikashɔn fɔ yuz wan bar lɛvɛl:

- 1.Bifo dɛn mɛzhɔ wit bar lɛvɛl, dɛn fɔ tek tɛm klin di say we dɛn de mɛzhɔ ɛn was dɛn dray fɔ chɛk fɔ difrɛn difrɛn tin dɛn lɛk skrat, rɔst, ɛn burr.

- 2.Bifo yu mɛzhɔ wit bar lɛvɛl, chɛk if di ziro pozishɔn kɔrɛkt. If nɔto kɔrɛkt wan, dɛn fɔ ajɔst di lɛvul we dɛn kin ajɔst, ɛn dɛn fɔ mek di fiks lɛvul bak.

- 3.We yu de mɛzhɔ wit bar lɛvɛl, dɛn fɔ avɔyd di inflɛns fɔ di tɛmpracha. di likwid insay di lεvεl gεt big impak pan tεmprachכ chenj dεm. So, dɛn fɔ pe atɛnshɔn to di inflɛns fɔ di an ɔt, dairekt san layt, ɛn bad briz na di lɛvɛl.

- 4.Insay di yus ɔf bar lɛvɛl, ridin fɔ bi na di pozishɔn fɔ di vertikal lɛvɛl fɔ ridyus di impak we paralaks gɛt pan di mɛzhɔmɛnt rizɔlt dɛn.

-

Produkt Paramita .

- Bar Level Gauge M Bar Level Gauge Spesifikasi MM: Akkurat: 0.02mm/m.

|

Produk Name . |

Spesifi kshɔn dɛn . |

Notis dɛn . |

|

Spirit Lɛvɛl dɛn . |

100*0,05mm, |

Na wan V-shaped groove de . |

|

Spirit Lɛvɛl dɛn . |

150*0,02mm, |

Na wan V-shaped groove de . |

|

Spirit Lɛvɛl dɛn . |

200*0,02mm, |

Na wan V-shaped groove de . |

|

Spirit Lɛvɛl dɛn . |

250*0,02mm, |

Na wan V-shaped groove de . |

|

Spirit Lɛvɛl dɛn . |

300*0,02mm, |

Na wan V-shaped groove de . |

Wetin na bar levul? Ki difrɛns frɔm freym lɛvɛl dɛn .

Ba lɛvɛl na kɔmpakt, linya prɛsishɔn tul we dɛn mek fɔ mɛzhɔ stret, alaynɛshɔn, ɛn inklin na flat ɔ silindrikal sɔfays—i fayn fɔ industrial aplikeshɔn usay spɛs na limited ɔ silindrikal wokpies (ɛgz., paip, mashin shaft) nid inspekshɔn. Na Storaen, wi bar levels ficha wan rugged cast iron bodi wit wan V-grooved base, alaw sekur plesment pan raun safa, en wan single presis bɔbul vayl fɔ detekt subtil tilt (as low as 0.02mm/m devyashon). Bɔt aw i difrɛn frɔm wan freym lɛvɛl? Lɛ wi brok di men difrɛns dɛn .:

1. Dizayn & Struktrɔ .

Bar Level: Linear, single-axis dizain wit V-shaped groove along di base (kritikal fɔ grip silindrikal objek) ɛn wan ɔ tu bɔbul vayl (ɔrizɔntal/vɛtikal). Layt ɛn pɔtabl, pafɛkt fɔ tayt ples ɔ fɔ mɛzhɔ di tɛm we yu de go.

Fram lɛvɛl (ɛgz., prɛsishɔn freym lɛvɛl): rɛktangul, 4-sayd freym wit bɔku bɔku mashin wok sɔfays (fɔnt, bak, ɔp, dɔŋ), sɔpɔt ɔl tu di ɔrizɔntal ɛn vertikal mɛzhɔmɛnt dɛn na flat plen dɛn. Bulkier bɔt mɔ versatile fɔ kɔmpleks, mɔlti-sɔfa inspekshɔn.

2. Fɔ mek dɛn ebul fɔ mɛzhɔ fɔs .

Bar Level: Speshaliz in silindrikal alaynɛshɔn (ɛgz., chɛk di stret we mashin tul gayd, paip instɔleshɔn) ɛn singl-plan flatnɛs. Di V-Groove de mek shɔ se dɛn gɛt stebul kɔntakt wit rawnd shaft, we de pul slip we dɛn de mɛzhɔ.

Fram Lɛvɛl: I fayn fɔ chɛk di flatnɛs chɛk dɛn we gɛt bɔku bɔku dimenshɔn (ɔrizɔntal, vertikal, skwea) pan big flat say dɛn lɛk mashin bays, kɔnstrɔkshɔn fɔm, ɔ wud wok tebul dɛn. I 4 edj dɛn de gi rɛfrɛns pɔynt fɔ kɔmpleks angul ɛn alaynɛshɔn wok dɛn.

3. Prɛsishɔn & aplikeshɔn sɛnɛriɔ dɛn .

Ɔl tu di tul dɛn de gi ay akkuracy (0.02mm/m standad na Storaen), bɔt dɛn trɛnk de na difrɛn yus kes dɛn:

Yuz bar lɛvɛl we yu de wok wit silindrikal kɔmpɔnɛnt dɛn, narrow rel dɛn, ɔ insay kɔnfyus spɛs usay kɔmpakt tul impɔtant.

Opt fɔ wan freym lɛvɛl (espɛshali wan prɛsishɔn freym lɛvɛl) we yu de mɛzhɔ flat sɔfays, chɛk rayt angul, ɔ nid simultaneous ɔrizɔntal/vɛtikal fidbak na wokshɔp, kɔnstrɔkshɔn sayt, ɔ CNC mashin sɛtup.

4. Storaen in ɛkspɛriɛns pan ɔl tu di kategori dɛn .

Na Storaen, wi injinia bar lɛvɛl fɔ rugged rilaybiliti—dɛn kast ayɛn bɔdi dɛn de agens kɔrɛshɔn ɛn impak, we di V-grɔv de ɔnda prɛsishɔn grindin fɔ mek shɔ se pafɛkt silindrikal fit. Wi freym levul, inklud di Premium Precision Frame Level Series, ficha aircraft-grade aluminium fram en dual-vial sistem fo unmatched multi-surface akkuracy.

If yu nid di portability fɔ wan bar lɛvɛl ɔ di versatility fɔ wan freym lɛvɛl, Storaen in industrial-grɛd tul dɛn de deliver di prɛsishɔn ɛn durabiliti yu prɔjek dɛn dimand. Ɛksplɔrɔ wi rɛnj tide fɔ fɛn di rayt mɛzhɔmɛnt sɔlvishɔn fɔ yu aplikeshɔn.

High-prɛsishɔn bar lɛvɛl: 0.02mm/m akkuracy spɛsifikɛshɔn dɛn

Na Storaen, wi Bar Level Series ridifayn prɛsishɔn mɛzhɔmɛnt wit industri-lida 0.02mm/m akkuracy—ɛnjɛnɛri fɔ task usay ivin di smɔl devyashon kin impɔk projɛkt sakses. Dis spɛsifikɛshɔn min se wi tul de detekt wan jɔs 0.02mm tilt ova 1 mita lɔng, we de sɛt di standad fɔ krichɔ alaynɛshɔn insay industrial, manufakchurin, ɛn mentenɛns aplikeshɔn dɛn.

1. Kalibrayt bɔbul vayl teknɔlɔji .

Di at fɔ wi bar lɛvɛl in prɛsishɔn na in metikulɔs kalibrayt bɔbul vayl, we dɛn bil wit ɔptik-grɛd glas ɛn tɛmpracha-stabiliz fluid fɔ minimiz ɛkspɛnshɔn mistek. εvri vayl de כndago wan 3-stεp kalibreshכn prכsεs, we de mek sכh se di bכbul de rεst εksakכt na sεntr we di sכfa de pafεktli כrizכnal כ vεtikal. Dis de pul di gɔs wok, we de gi klia, ripit ridin ivin na say dɛn we de chenj chenj.

2. Prɛsishɔn-mashin V-grɔv bays .

Wi bar level gɛt V-shaped groove graɔn to maykron-lɛvel tolɛreshɔn, we de mek shɔ se yu kɔntakt wit silindrikal sɔfays lɛk mashin shaft, paip, ɔ rel gayd. Di groove in 120° angle ɛn miro-finish surface (RA ≤ 0.8μm) de pul slip ɛn mɛzhɔmɛnt inkɔnsistens, we de mek i fayn fɔ mek dɛn chɛk di rawnd wokpies dɛn stret, usay akkuracy na nɔ-nɛgɔshiabl.

3. Rugged konstrakshɔn fɔ stebul pefɔmɛns

We dɛn put wi na wan ɔt-trit kast ayɛn bɔdi, wi bar lɛvɛl de agens di tɛm we di ples wam ɛn di mɛkanikal strɛs, we de mek wi kɔntinyu fɔ gɛt 0.02mm/m akkuracy akɔdin to -10°C to 50°C tɛmpracha. Di solid kor dizayn de dampen vaybreshɔn frɔm industrial mashin, we di anti-kɔrosiv ɛnamel kɔtin de protɛkt frɔm ɔyl, kulant, ɛn mɔs, we rili impɔtant fɔ lɔng tɛm prɛsishɔn na harsh wokshɔp ɛnvayrɔmɛnt.

4. Aplikeshɔn dɛn usay prɛsishɔn impɔtant pas ɔl .

Frɔm alaynɛshɔn CNC mashin tul gayd dɛn to verify di stret we fɔ kɔnvaysɔ rɔla ɔ paip layn instɔleshɔn dɛn, wi ay-prɛsishɔn bar lɛvɛl de delivr unmatched rilaybiliti. Injinia ɛn tɛknishian dɛn trɔst in 0.02mm/m raytin fɔ .:

Mashin Tul Sɛtup: Fɔ mek shɔ se spindle alaynɛshɔn fɔ mek dɛn nɔ gɛt wokpies dɛfɛkt dɛn .

Aerospace komponent inspekshɔn: validet silindrikal pat tolɛreshɔn dɛn .

Hevi ekwipmɛnt mentenɛns: kalibrayt haydrolik silinda shaft fɔ smol ɔpreshɔn

5. Storaen in kɔmitmɛnt fɔ kɔrɛkt .

Ɛvri bar lɛvɛl de kɔmɔt na wi faktri wit wan traysabl kalibreshɔn sɛtifiket, we de kɔnfɔm fɔ fala di ISO 17025 standad. Wi de sɔbjɛkt ɛni tul to 12-pɔynt kwaliti ɔdit, we inklud flatnɛs tɛst, bɔbul stebiliti chɛk, ɛn tɛmpracha sayklis, fɔ garanti se di 0.02mm/m spɛsifikɛshɔn de ol tru ɔlsay na in layfsaykl.

We yu projɛkt de aks fɔ mɛzhɔ yu kin stek yu reputeshɔn pan, pik di Storaen bar lɛvɛl—we 0.02mm/m akkuracy nɔto jɔs wan spɛsifikɛshɔn, bɔt na prɔmis fɔ prɛsishɔn we nɔ gɛt kɔmprɔmis.

Bar Level Applications: Measuring Cylindrical Workpieces & V-Grooves

Insay industrial mɛzhɔmɛnt, bar lɛvɛl dɛn ɛksɛl insay prɛsishɔn wok dɛn we involv silindrikal sɔfays ɛn V-shaped strɔkchɔ dɛn—rɔl usay dɛn spɛshal dizayn pas jenɛral tul dɛn. Na Storaen, wi Bar Level Series na ensinia fɔ takɛl dɛn chalenj ya wit akkuracy ɛn rilaybiliti we nɔ gɛt wan kɔmpitishɔn, we mek i bi di prɛferɛd chuk fɔ pɔshɔnal dɛn we de wok wit silindrikal wokpies, mashin tul gayd, ɛn V-grooved kɔmpɔnɛnt dɛn.

1. Silindrikal wokpies alaynɛshɔn & straytnɛs chɛk dɛn .

A bar level’s defining feature—di v-grooved base—de mek wan sikrit, stebul intafeys wit rawnd sɔfays, lɛk .:

Mashin Tul Shaft: We yu de alaynɛd CNC spindle shaft ɔ kɔnvayɔ rɔla, Storaen in bar lɛvɛl de mek shɔ se i nɔ gɛt bɛtɛ rɔnaut bay we i de no di maykro-tilt (as low as 0.02mm/m) along di silinda in lɔnjitudinal aks. Di V-groove in 120° angle ɛn prɛsishɔn-grɔn sɔfays (RA ≤ 0.8μm) kɔnfɔm pafɛkt wan to silindrikal jɔyometri, we de pul slip ɛn mɛzhɔmɛnt mistek.

Pipeline installations: Insay ɔyl ɛn gas ɔ industrial paip sistem, wi bar lɛvɛl de chɛk di stret we di paip sɛgmɛnt dɛn de we dɛn de asembli, we de mek dɛn nɔ alayns we kin mek di flɔ nɔ ebul fɔ wok ɔ di strɔkchɔ strɛs. I kɔmpakt dizayn fit izi wan insay tayt kɔndukt spɛs, usay bɔku bɔku tul dɛn nɔ ebul fɔ rich.

2. V-Groove Komponent Kalibreshɔn .

V-grooved structures—kɔmɔn insay fiks, gej, ɛn rel sistɛm—de fɔ prɛsis angle ɛn flatnɛs chɛk. Storaen in bar level excels ya by:

Testing V-Groove Squareness: Fɔ put di lɛvɛl akɔdin to tu ɔpɔsin V-grooves (ɛgz., insay mashin tul slayd) de sho angul devyashon, we de mek shɔ se kɔmpɔnɛnt dɛn de mate kɔrɛkt wan fɔ mek di linya muv fayn fayn wan.

Aligning V-guided rails: In automated manufacturing lines, wi bar level de mek shɔ se V-guided rails de pafɛkt paralel, minimiz wear pan muv kariɔt ɛn mentɛn posishunal akkuracy fɔ robotik arm ɔ matirial handler.

3. Ɔtomotiv Prɛsishɔn Task dɛn .

Na industri usay dɛn de mɛzhɔ tolɛreshɔn dɛn na maykron .:

Ɔtomotiv Asɛmbli: We dɛn de instɔl di pawa tren, wi tul de mek shɔ se kamshaft ɛn krankshaft dɛn de alaynɛd insay spɛsifikɛshɔn, we de mek di kɔst nɔ de wok fayn fɔ di layn.

4. Wetin mek di Storaen bar lɛvɛl dɛn de lid insay silindrikal mɛzhɔmɛnt .

Wi bar levul dem kombayn tri ki advantej fo dis aplikeshon dem .:

Rugged Cast Iron Construction: I de bia di impak ɛn di thermal fluktueshɔn dɛn na di harsh wokshɔp dɛn, fɔ mek dɛn kɔntinyu fɔ yuz am kɔrɛkt wan fɔ lɔng tɛm we dɛn dɔn yuz am bɔku bɔku tɛm.

Optik-grɛd bɔbul vayl dɛn: Gi instant, unambiguous ridin dɛn ivin insay lɔw-layt kɔndishɔn, ridyus mɛzhɔmɛnt tɛm bay 30% kɔmpia to jenɛrik lɛvɛl dɛn.

Traceable kalibreshɔn: Ɛvri tul kam wit ISO 17025-sɛtifiket ripɔt, we de garanti in 0.02mm/m akkuracy mit intanashɔnal standad fɔ impɔtant wok dɛn.

If yu de alaynɛs wan shaft ɔ manej wan kɔmpleks industrial instɔleshɔn, Storaen in bar lɛvɛl de deliver di prɛsishɔn ɛn durabiliti we nid fɔ kip silindrikal wokpies ɛn V-grooved kɔmpɔnɛnt dɛn insay tolɛreshɔn. Trust di tul we dɛn mek fɔ di spɛshal chalenj dɛm fɔ mɛzhɔmɛnt rawnd-sɔfa, bikɔs insay manufakchurin, di smɔl kɔv kin mek di big difrɛns.

Related PRODUCTS