- danish

- english

- afrikaans

- albanian

- amharic

- arabic

- armenian

- assamese

- aymara

- azerbaijani

- bambara

- basque

- belarusian

- bengali

- bhojpuri

- bosnian

- bulgarian

- burmese

- catalan

- cebuano

- corsican

- creole

- croatian

- czech

- deutsch

- dhivehi

- dogrid

- dutch

- estonian

- ewe

- filipino

- finnish

- french

- frisian

- galician

- georgian

- greek

- guarani

- gujarati

- haitian_creole

- hausa

- hawaiian

- hebrew

- hindi

- hungarian

- icelandic

- igbo

- indonesian

- irish

- italian

- japanese

- kannada

- khmer

- kinyarwanda

- korean

- kurdish

- kurdish_sorani

- kyrgyz

- lao

- latin

- latvian

- lithuanian

- luganda

- luxembourgish

- macedonian

- maithili

- malay

- malayalam

- maltese

- maori

- marathi

- nepali

- norwegian

- nyanja

- oromo

- pashto

- persian

- polish

- portuguese

- punjabi

- quechua

- romanian

- russian

- samoan

- sanskrit

- scottish_gaelic

- shona

- sindhi

- singapore

- slovak

- slovene

- somali

- spanish

- swahili

- swedish

- tajik

- tamil

- tatar

- telugu

- thai

- turkish

- turkmen

- twi

- ukrainian

- urdu

- vietnamese

- welsh

- yiddish

- yoruba

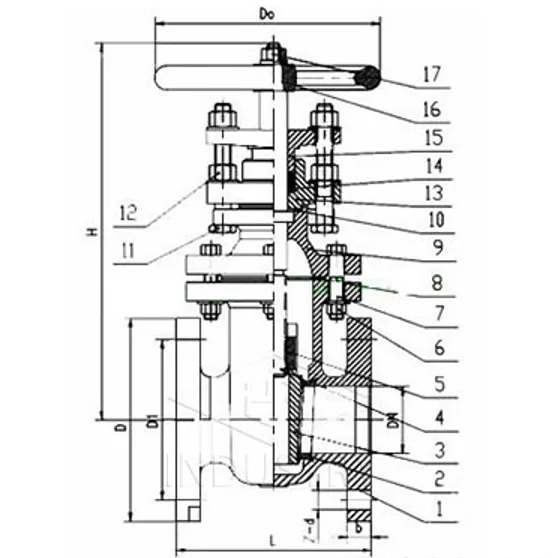

Had sil get valv .

Di diskripshɔn fɔ di prɔdak .

Uctil Iron Concealed Lever Hard Seal Gate Valves (DN40-DN2000), Prɛshɔn: (PN6~PN25), ɔl di prɔdak dɛn gɛt sɛtifiket bay CE prɛshɔn ikwipmɛnt.

Sayz renj: 1 1/2′-12’/DN40-DN300.

Opareshɔn mɔd: manual/gia bɔks/numatik/ilɛktrik

Prɛshɔn we de wok: PN16 .

Vali Bɔdi Matirial: Kast Ayɔn / Ductile Iron

Valv Plɛt Matirial: Kast Ayɔn/Dɔktayl Ayɔn

Valve sit matiryal: Brass/Bronze/Stenless Steel

Valv stem matirial: SS .

Gland Material: Kast Ayɔn / Ductile Iron

Aplikeshɔn: Wata, Ɔyl ɛn Gas

Shell Test: 1.5 tɛm

Sit tɛst: 1.1 tɛm

Di we aw dɛn de pe: T/T

Lid tɛm: 5-30 dez

Di tin dɛn we dɛn de yuz fɔ mek di prɔdak .

1. Fɔ pik fayn fayn tin dɛn fayn fayn wan, we go gri wit di standad dɛn we gɛt fɔ du wit am, ɛn di tin dɛn we gɛt ay kwaliti.

2. Di valv fulɔp mit di rikwaymɛnt dɛn fɔ di standad, wit rili silin, fayn fayn pefɔmɛns ɛn fayn fayn apia.

3. Di siling pe na advans ɛn rizin. Di silin surfaces of di get en di valve sit na reliable, high hardness, wear resistance, high tempereture resistance, en high tempereture resistance. Gud koroshɔn ɛn skrach rɛsistɛns ɛn lɔng layf.

4. Afta dɛn dɔn kwench ɛn temper ɛn sɔfa na di nitriding tritmɛnt, di valv stem gɛt gud kɔrɛshɔn rɛsistɛns, skrach rɛsistɛns ɛn wear rɛsistɛns.

5. I adopt wedge-type elastic gate structure, midul ɛn big dayamita dɛn gɛt thrust bearings, di frikshɔn smɔl, ɛn i gɛt impak manual ɔpreshɔn, we dɛn kin opin ɛn klos izi wan.

Dizayn Advantej dɛn .

1. Di fluid resistans smɔl, ɛn di silin surface nɔ brus ɛn kɔrod bay di medium.

2. I de sev tray fɔ opin ɛn lɔk.

3. Di flɔ dairekshɔn fɔ di mɛdiɔm nɔ de stɔp, i nɔ de ambɔg di flɔ, ɛn i nɔ de ridyus di prɛshɔn.

4. Simpul shep, shɔt strɔkchɔ lɔng, gud manufakchurin teknɔlɔji ɛn waid aplikeshɔn rɛnj.

Fild fɔ aplikeshɔn .

Sayz renj: DN40 to DN300.

Tempracha: (-)29°C to 425℃

Prɛshɔn we dɛn kin alaw fɔ wok:PN16 .

Get valv de yuz bɔku bɔku wan na petrokemik plant, mɛtalɔji, wata tritmɛnt, tɛmral pawa plant ɛn ɔda ɔyl ɛn wata vaypa paip layn fɔ kɔnɛkt ɔ kɔt di mɛdiɔm na di paip.

Instɔlɛshɔn ɛn Mentɛnans .

1. Dɛn nɔ de alaw fɔ yuz an-wil, handel ɛn transmishɔn mɛkanism fɔ yuz fɔ lif, ɛn dɛn nɔ gri fɔ mek dɛn kɔlishin.

2. Di dabl get valv fɔ instɔl vertikal (dat na, di valv stem de na di vertikal pozishɔn ɛn di hanwil de ɔp).

3. Di get valv wit baypas valv fɔ opin bifo yu opin (fɔ balans di prɛshɔn difrɛns bitwin inlet ɛn ɔlt ɛn ridyus di fɔs fɔs).

4. Di get valv wit drayv mɛkanizm fɔ instɔl akɔdin to di prodak manyual.

5. If dɛn opin ɛn lɔk di valv bɔku tɛm, lubrik wan tɛm insay di mɔnt.

Produkt Paramita .

|

DN |

Inch |

L |

PCD na di . |

N-φd na di . |

FOD na |

|

40 |

1 1/2" |

140 |

98.4 |

4-18 |

165 |

|

50 |

2" |

146 |

114 |

4-18 |

165 |

|

65 |

2 1/2" |

159 |

127 |

4-18 |

185 |

|

80 |

3" |

165 |

146 |

8-18 |

200 |

|

100 |

4" |

172 |

178 |

8-18 |

220 |

|

125 |

5" |

191 |

210 |

8-18 |

250 |

|

150 |

6" |

210 |

235 |

8-22 |

285 |

|

200 |

8" |

241 |

292 |

12-22 |

340 |

|

250 |

10" |

273 |

356 |

12-26 |

405 |

|

300 |

12" |

305 |

406 |

12-26 |

460 |

Advantej dɛn fɔ had sil get valv dɛn .

Wan impɔtant tin we de insay di had sil get valv dɛn na dɛn supia silin kapasiti. Dɛn mek dɛn valv dɛn ya wit wan strɔng we fɔ sidɔm we de mek di lik nɔ de, ɛn dis kin mek ɛni wata ɔ gas nɔ pas we di valv de na say we dɛn lɔk. Dis kwaliti impɔtant mɔ na aplikeshɔn usay fɔ mek dɛn nɔ gɛt kɔntaminɛshɔn ɛn fɔ protɛkt di envayrɔmɛnt rili impɔtant.

Wan ɔda impɔtant advantej fɔ had sil get valv na dɛn ɛkstend layfspan. Dɛn mek am wit tin dɛn we go de fɔ lɔng tɛm lɛk stenlɛs stiɛl ɔ ɔda had alɔy dɛn, dɛn valv dɛn ya dɛn dɔn ɛnjinɛri fɔ bia wit di kɔndishɔn dɛn we de wok tranga wan, we inklud ay prɛshɔn ɛn di tɛmpracha we pasmak. Dis durabiliti translet to lɔwa mentenɛns kɔst ɛn less frɛkuɛnt riplesmɛnt, mek dɛn bi kɔst-ɛfɛktiv sɔlvishɔn fɔ industrial aplikeshɔn.

Apat frɔm dat, had sil get valv dɛn de gi fayn fayn flɔ kwaliti dɛn. Dɛn dizayn alaw fɔ minimal flɔ rɛsistɛns, we de ɛnabul smol ɛn efishɔnal fluid transfa. Dis nɔ jɔs de ɛp fɔ mek di sistɛm wok fayn bɔt i de ridyus di ɛnaji we dɛn de yuz, we de alaynɛd wit di mɔdan sastaynabiliti gol dɛn na difrɛn sɛktɔ dɛn, we inklud wata tritmɛnt, kemikal we dɛn de mek, ɛn ɔyl ɛn gas.

Dɔn bak, di izi we aw di had sil get valv dɛn de wok kin ɛp fɔ mek pipul dɛn lɛk dɛn. Dɛn kin ɔpres dɛn wit dɛn an ɔ ɔtomɛtik wan, we kin alaw fɔ mek dɛn ebul fɔ chenj di we aw dɛn kin du difrɛn difrɛn tin dɛn we dɛn kin du. Dis adaptabiliti de mek shɔ se sistem dɛn kin tayla fɔ mit spɛshal ɔpreshɔnal nid dɛn we nɔ go kɔmprɔmis pan efyushɔn ɔ sef.

Fɔ dɔn, di had sil get valv dɛn de gi bɔku bɛnifit dɛn, lɛk fɔ mek di silin wok fayn, fɔ mek i go te, fɔ mek i gɛt fayn fayn flɔ, ɛn fɔ mek i izi fɔ wok. Dɛn bɛnifit ya de mek dɛn bi wan impɔtant pat pan bɔku industrial prɔses, we de mek shɔ se dɛn gɛt rilaybiliti ɛn efyushɔn. As di industri dɛn de kɔntinyu fɔ evolv, di wok we di had sil get valv dɛn de du nɔ go gɛt wan dawt se dɛn go gro, we go mek dɛn pozishɔn strɔng as di men tin we de insay di mɔdan injinɛri sɔlvishɔn dɛn.

Hard Seal Gate Valves FAQ dɛn .

Wetin na wan had sil get valv, ɛn wetin na in praymari aplikeshɔn dɛn?

Wan had sil get valv na wan kayn valv we de mek shɔ se i gɛt tayt sil wit smɔl lik, we de mek i fayn fɔ aplikeshɔn dɛn we nid fɔ flɔ we nɔ gɛt ɛnitin fɔ ambɔg. Dɛn kin yuz dɛn na industri dɛn lɛk wata sapɔt, petrolium, ɛn kemikal prɔses, usay dɛn kin rili ayzolayshɔn ɛn kɔntrol di flɔ we di wata de flɔ rili impɔtant. Dɛn strɔng dizayn de ɛp fɔ handle fluid prɛshɔn ɛn tɛmpracha ekstrim, we de mek dɛn fit fɔ ɔl tu di industrial ɛn kɔmɛshɔnal sɛtin.

Us matirial dɛn dɛn kin yuz fɔ bil had sil get valv dɛn?

Wi had sil get valv dɛn kin tipikul fɔ bil frɔm ay kwaliti matirial dɛn lɛk stenlɛs stiɛl, kast ayɛn, ɛn kabɔn stɛl, we dɛn mek fɔ mek i go te ɛn fɔ liv lɔng. Di siling surfaces dem engineer fo optimal pefomans, plenti taims featur hard facing materials we enhans dem resistance to wear en koroshon. Dipen pan yu patikyula nid dɛm, wi de gi valv dɛm we kin ebul fɔ handle difrɛn kemikal ɛn fluid dɛm fayn fayn wan.

Aw a go no us saiz had sil get valv rayt fɔ mi sistɛm?

Fɔ pik di rayt saiz fɔ yu had sil get valv na impɔtant tin fɔ mek yu wok fayn fayn wan. Yu fɔ tink bɔt di dayamita fɔ di paip, di flɔ rit we dɛn nid, ɛn ɛni patikyula sistɛm we dɛn nid lɛk prɛshɔn ɛn tɛmpracha rɛytin. If yu nɔ shɔ, wi kin advays yu fɔ tɔk to pɔsin we sabi du in wok ɔ fɔ rich to wi kɔstɔma savis tim fɔ ɛp yu; Wi kin gi gayd bays pan yu sistɛm in spɛsifikɛshɔn dɛn fɔ mek shɔ se yu pik di pafɛkt valv.

Yu tink se di had sil get valv dɛn izi fɔ instɔl ɛn mentein?

Yes, dɛn mek di had sil get valv dɛn fɔ instɔl ɛn mentenɛns stret. Dɛn kin kam wit kɔmprɛhɛnsif instɔleshɔn instrɔkshɔn dɛn ɛn dɛn kin instɔl dɛn na difrɛn ɔriɛnteshɔn dɛn. Rigyul mentenɛns na smɔl tin, bɔku tɛm dɛn kin nid jɔs wan wan tɛm inspekshɔn fɔ mek shɔ se di sil dɛn kɔntinyu fɔ wok. Wi tim de fɔ gi sɔpɔt ɛn advays bɔt mentenɛns prosidyuz fɔ ɛp fɔ mek di valv in layf lɔng.

Yu tink se di had sil get valv dɛn de fala di standad fɔ di industri?

Absolutely, wi had sil get valv dem we dem mek fo mit o pas di indastri standad laik ANSI, API, and ASME. Wi de mek shɔ se ɛni valv de du strɔng tɛst fɔ kwaliti ɛn pefɔmɛns, we de gi yu wan prɔdak we yu kin trɔst fɔ yu aplikeshɔn dɛn. If yu nid spɛshal sɛtifiket ɔ kɔmplians dɔkyumentri, duya mek wi no, ɛn wi go gladi fɔ ɛp.

Yu tink se dɛn kin yuz had sil get valv dɛn na ay-prɛshɔn aplikeshɔn dɛn?

Yes, had sil get valv dem de wel-suited fo hai-pressure aplikeshon. Dɛn gɛt strɔng kɔnstrɔkshɔn ɛn advans siling tɛnkɔlɔji dɛn we dɛn mek fɔ bia wit dɛn kayn kɔndishɔn dɛn de we de mek dɛn nid fɔ du dat. We yu de pik wan valv fɔ yuz ay prɛshɔn, mek shɔ se yu chɛk in prɛshɔn rɛytin ɛn tɔk to wi tim if yu gɛt ɛni kwɛstyɔn; Wi kin rikomɛnd di bɛst opshɔn dɛn we dɛn mek fɔ yu patikyula tin dɛn we yu nid.

Related PRODUCTS