- danish

- english

- afrikaans

- albanian

- amharic

- arabic

- armenian

- assamese

- aymara

- azerbaijani

- bambara

- basque

- belarusian

- bengali

- bhojpuri

- bosnian

- bulgarian

- burmese

- catalan

- cebuano

- corsican

- creole

- croatian

- czech

- deutsch

- dhivehi

- dogrid

- dutch

- estonian

- ewe

- filipino

- finnish

- french

- frisian

- galician

- georgian

- greek

- guarani

- gujarati

- haitian_creole

- hausa

- hawaiian

- hebrew

- hindi

- hungarian

- icelandic

- igbo

- indonesian

- irish

- italian

- japanese

- kannada

- khmer

- kinyarwanda

- korean

- kurdish

- kurdish_sorani

- kyrgyz

- lao

- latin

- latvian

- lithuanian

- luganda

- luxembourgish

- macedonian

- maithili

- malay

- malayalam

- maltese

- maori

- marathi

- nepali

- norwegian

- nyanja

- oromo

- pashto

- persian

- polish

- portuguese

- punjabi

- quechua

- romanian

- russian

- samoan

- sanskrit

- scottish_gaelic

- shona

- sindhi

- singapore

- slovak

- slovene

- somali

- spanish

- swahili

- swedish

- tajik

- tamil

- tatar

- telugu

- thai

- turkish

- turkmen

- twi

- ukrainian

- urdu

- vietnamese

- welsh

- yiddish

- yoruba

Slow klosing chɛk valv .

Di diskripshɔn fɔ di prɔdak .

300x slo-klos mufla chɛk valv gɛt wan nyu strɔkchɔ, gud siling ifɛkt, lɔw rɛsistɛns, big flɔ, lɔng savis layf ɛn ɔda tin dɛn. Kin kɔntrol di spid we di men valv opin ɔ klos, kin ajɔst wit di scene to wan gud wok kɔndishɔn, kin bi wata hama fenomen, fɔ ajɔst di ifɛkt fɔ slo-klos mufla.

Di advantej fɔ slo klosing chɛk valv dɛn na mɔdan aplikeshɔn dɛn .

Insay di eria fɔ di fluid kɔntrol sistɛm dɛn, di chukchuk fɔ valv tɛknɔlɔji na impɔtant tin fɔ mek shɔ se dɛn ebul fɔ wok fayn ɛn fɔ mek dɛn liv lɔng. Wan pan di nyu tin dɛn we gɛt fɔ du wit dis fild na di slo klosing chɛk valv, we de gi bɔku bɛnifit fɔ difrɛn industrial aplikeshɔn dɛn.

Fɔs ɛn di men tin, di men bɛnifit fɔ wan chɛk valv we de lɔk sloslo na in ebul fɔ mek wata nɔ hama, we na tin we kin apin we dɛn fos di wata we de kɔmɔt na di bɔdi fɔ stɔp ɔ chenj di say we i de go wantɛm wantɛm. Dis kin mek dɛn gɛt siriɔs prɛshɔn sɔj na di paip layn dɛn, we kin mek ɔl tu di paip sistem dɛn ɛn di ikwipmɛnt dɛn we gɛt fɔ du wit am, pwɛl. Di slo klos ficha fɔ dɛn valv ya de alaw fɔ mek di flɔ velositi go dɔŋ smɔl smɔl, ifɛktiv wan mitigate shɔk wev ɛn protɛkt infrastukchɔ.

Plɛnti mɔ, slo klosing chɛk valv dɛn na impɔtant tin fɔ ɛp fɔ mek di ɔpreshɔnal efyushɔn go bifo. bay we dεn de kכntro di spid we di valv dεm de kכlכs, dεn divays dεm ya de ridyus di enεji we de lכs di tεm we di fכs wata de transit εn i de mek di tכbulεns nכ de insay di sistεm. Dis efyushɔn de translet to lɔwa ɔpreshɔnal kɔst ɛn impɔtant ɔvala sistɛm rilaybiliti, we de mek i bi favɔret chuk akɔdin to difrɛn sɛktɔ dɛn, we inklud wata tritmɛnt, ɔyl ɛn gas, ɛn kemikal prɔsesin.

Wan ɔda impɔtant advantej na di inkris layfspan fɔ di valv sɛf. Tradishonal chɛk valv, we dɛn kin lɔk kwik kwik wan, bɔku tɛm kin gɛt pasmak wear ɛn tear. Difrɛn frɔm dat, slo klosing chɛk valv dɛn kin gɛt smɔl strɛs we dɛn de wok, we kin mek dɛn ridyus di kɔst fɔ mentenɛns ɛn fɔ mek dɛn gɛt lɔng savis layf. Dis durabiliti na patikyula advantej in ay-dimand envairoment usay regyula maintenance kin lid to kos dauntaym.

Fɔ dɔn, di bɛnifit dɛn we slo klosing chɛk valv dɛn gɛt na bɔku bɔku wan. Dɛn ebul fɔ mitigate wata hama, ɛp fɔ mek di opareshɔn wok fayn, ɛn ɛkstɛnd di ikwipmɛnt layfspan de mek dɛn bi wan impɔtant pat pan di mɔdan fluid sistɛm dɛn. As di industri dɛn de kɔntinyu fɔ luk fɔ rilibul ɛn kɔst-ɛfɛktiv sɔlvishɔn, di pɔpulɛshɔn fɔ di slo klosing chɛk valv de sɛt fɔ go ɔp, we de sɔlidify in pozishɔn as ki pleya insay ifɛktiv fluid kɔntrol manejmɛnt.

"Water Hammer Buster": Aw 300x Slow Klosing Valve Tames 99% Pipeline Surges wit dual-chamber dizain

Storaen in slo-klos chɛk valv de ridifayn paip layn sef bay we i intagret wan rivɔlɔshɔnari dual-wata-chɛmba sistɛm, spɛshal wan we dɛn dɔn ɛnjɛnɛri fɔ pul di pwɛl pwɛl ifɛkt dɛn we wata hama gɛt pan pɔmp sistɛm dɛn. Nɔ lɛk tradishɔnal nɔ-ritɔn chɛk valv dɛn we de risk fɔ lɔk wantɛm wantɛm ɛn prɛshɔn sɔj, wi 300x mɔdel de kam togɛda fast initial shutɔf wit kɔntrol smɔl smɔl klos, we mek i bi di ɔltimat sɔlvishɔn fɔ ay-rayz bildin dɛn, industrial paip layn dɛn, ɛn wata tritmɛnt plant dɛn.

Di majik fɔ dual-chamber teknɔlɔji .

Na di kɔr fɔ dis bakflɔ prɛvɛnt chɛk valv lay wan tu-pat haydrolik mɛkanizm .:

1. Upper & Lower Water Chambers: Wan piston-stayl disk de sheb di valv insay tu chɛmba, we dɛn kɔnɛkt bay wan prɛsishɔn nidul valv we de rigul di wata we de flɔ bitwin dɛn.

Stej 1: Rapid imejensi shutof (80% strok insay 2 sɛkɔn): We di pɔmp stɔp, di disk slam dɛn kin lɔk kwik kwik wan fɔ arɛst ay-vɛlositi bakflɔ, we kin mek di pɔmp ɛn valv dɛn we kin pwɛl kwik kwik wan, we rili impɔtant fɔ protɛkt dia dia ikwipmɛnt dɛn lɛk sɛntrifugal pɔmp dɛn.

Stej 2: smɔl smɔl prɛshɔn rilif (we dɛn de kip 20% strok ova 10–60 sɛkɔn): di nidul valv de kɔntrol di wata we de flɔ frɔm di ɔpa to di ɔda chɛmba, we de alaw di disk fɔ lɔk slo ɛn ivin, we de dissipayt di rɛsidɔl prɛshɔn ɛn stɔp di wata hama pik dɛn to ≤1.5x wok prɛshɔn—99% mɔ ifɛktiv pas standad bakkɛk valv dɛn.

Wetin mek dual-chamber pas ɔda kayn chɛk valv dɛn .

Noise & Vibration Control: Di slo fainal klos we dɛn klos de pul di “wata hama bang,” we de ridyus di nɔys bay 40% we yu kɔmpia am wit di mɔdel dɛn we de klos kwik—i fayn fɔ di say dɛn we pipul dɛn de liv ɔ di say dɛn we dɛn de mek nɔys.

Ekstend Ikwipmɛnt Layf: Bay we yu minimiz prɛshɔn sɔj, i de kɔt pɔmp sil wear bay 30% ɛn valv sit ɛrɔshɔn bay 50%, we de autlast kɔvɛnshɔnal 1/2 wan-we chɛk valv ɔ 2-inch chɛk valv dɛn na harsh ɛnvayrɔmɛnt.

Versatile dizain fɔ difrɛn aplikeshɔn dɛn .

I de insay saiz frɔm 1/2 chɛk valv (DN15) to 2-inch chɛk valv (DN50) ɛn biyɔn (we go rich DN600), di 300x mɔdel de adap to difrɛn sistem dɛn:

Di tin dɛn we yu go ebul fɔ pik frɔm .:

Daktayl ayɛn: kɔst-ɛfɛktiv fɔ industrial wata/gas (1.0–2.5MPa, -10°C–80°C).

Brass: Kɔroshɔn-rɛsistant fɔ pɔtabl wata ɔ marin aplikeshɔn (i fayn fɔ stenlɛs stiɛl chɛk valv ɔltɛrnativ dɛn na lɔw-prɛshɔn sɛtup dɛn).

stenlɛs stiɛl 316: Hevi-duti fɔ kemikal midia ɔ ay-tɛmpracha sɛnɛriɔ (we go rich 150°C).

Instɔlɛshɔn Fleksibiliti: Flanged Kɔnɛkshɔn (RF/FF) Kɔmplit wit ASME B16.5 ɛn GB/T 17241.6, we fit seamles insay ɔl tu di nyu paip layn dɛn ɛn retrofiting prɔjek dɛn.

Ki Pɛfɔmɛns Mɛtrik dɛn .

Low prɛshɔn aktiveshɔn: bigin fɔ klos na jɔs 0.05MPa, we de mek shɔ se dɛn gɛt rilibul ɔpreshɔn na lɔw-hɛd sistɛm.

Minimal flɔ rɛsistɛns: Wan strimlayn disk dizayn de ridyus prɛshɔn drɔp bay 25% kɔmpia to swing-tayp chɛk valv dɛn, ɔptimayz ɛnaji efyushɔn.

Saykl Layf: 50,000+ opareshɔn dɛn we nɔ gɛt sit wear—tu tɛm di industri avɛrej fɔ chɛk valv dɛn we de lɔk sloslo.

Pik di rayt chɛk valv fɔ yu sistem .

If yu nid 1/1/2 chɛk valv fɔ wan smɔl HVAC lɔp ɔ wan big DN300 mɔdel fɔ industrial pɔmp, Storaen in dual-chamber teknɔlɔji de mek shɔ se protɛkshɔn nɔ de. Nɔ lɛk jenɛrik difrɛn kayn chɛk valv dɛn we de kɔmprɔmis pan sef ɔ efyushɔn, wi 300x mɔdel de gi tri impɔtant bɛnifit dɛn insay wan: bakflɔ prɛvenshɔn, wata hama ɛliminɛshɔn, ɛn nɔys ridɔkshɔn.

Upgrade yu pipeline safety tide wit di slo-klosing check valve we engineers trust. Ɛksplɔr di Storaen in rɛnj ɛn diskɔba aw intɛligent dizayn de transfɔm fluid kɔntrol—bikɔs insay paip layn, prɛvɛnshɔn bɛtɛ ɔltɛm pas fɔ ripɛnt.

Cast Iron vs Brass Materials: Wan kɔrɛshɔn-rɛsistant sɛlɛkshɔn gayd fɔ slo klosing chɛk valv dɛn

Fɔ pik di rayt matirial fɔ yu chɛk valv we de lɔk sloslo na impɔtant tin fɔ mek shɔ se i liv lɔng ɛn wok, mɔ we yu de dil wit kɔrosiv midia. Storaen de gi tu praymari opshɔn dɛn—kas ayɛn ɛn bras—ɛni wan dɛn we dɛn mek fɔ patikyula industri ɛn kɔmɛshɔnal aplikeshɔn dɛn. Dis gayd de ɛp yu fɔ go na dɛn difrɛns ɛn pik di bɛst sɔlvishɔn fɔ yu paip layn nid dɛn, we yu de fɛn aw dɛn kɔmpia to ɔda kayn chɛk valv dɛn.

1. Kast Ayɔn: Hevi-duti durabiliti fɔ industrial rigors

Chek valv cast iron (eg, QT450 ductile iron) na di go-to choice fɔ harsh, ay-prɛshɔn ɛnvayrɔmɛnt. Wit tɛnsiɛl trɛnk we na 450MPa, i de bia wit prɛshɔn we go rich 2.5MPa ɛn tɛmpracha frɔm -10°C to 80°C, we mek i fayn fɔ abraziv fluid dɛn lɛk siwej, industrial wata, ɔ patikyula-laden midia. I rugged surface texture de mek shɔ se wan rilibul sil fɔ nɔ-ritɔn chɛk valv dɛn, we de minimiz lik na ay-flɔ sistɛm dɛn. Wail naturally resistant to mild corrosives (pH 6–8), opshonal epoxy coatings de enhans protekshɔn agens moderate acids/alkalis. Bɔt, i nɔ fayn fɔ si wata ɔ agresiv kemikal—opt fɔ stenlɛs stiɛl chɛk valv dɛn na dɛn kes dɛn de.

Di bɛst fɔ: Indastrial paip layn, west wata plant, ɛn HVAC sistem usay abrashɔn ɛn ay prɛshɔn na kɔnsyans. pe fayn fayn wan wit payɔt-ɔpreshɔn chɛk valv dɛn na ɔtomatik pɔmp steshɔn dɛn.

2. Brass: Prɛsishɔn ɛn klin fɔ klin midia

Bras chɛk valv dɛn (ɛgz., HPB59-1 lid-fri bras) ɛksɛl insay aplikeshɔn dɛn we nid hajɛns ɛn rɛsistɛns to nɔ-agresiv fluid dɛn. Dɛn smol smol surface finish (RA 3.2) mit FDA standad fɔ pɔtabl wata ɛn fud-grɛd paip layn, we mek dɛn fayn fɔ drink wata sistɛm ɔ marin sɛtup. Layt pas kast ayɛn, dɛn kin mek am izi fɔ instɔl insay tayt ples dɛn, lɛk rezidenshɛl plaba wit 1/2 wan-we chɛk valv dɛn. Brass nɔ de gri fɔ gɛt fresh wata, stim (≤150°C), ɛn asid dɛn we nɔ de ɔksijɛn bɔt i kin kɔrɛkt insay amonia ɔ ay-tɛmpracha si wata—we de tink bɔt nikel-plet kemikal chɛk valv dɛn fɔ dɛn kayn kɔndishɔn dɛn de.

Di bɛst fɔ: Drinkin wata sistɛm, marin aplikeshɔn, ɛn smɔl-smɔl industrial sɛtup (ɛgz., 2-inch chɛk valv dɛn na bɔyl fid layn dɛn). Perfekt fɔ bakflɔ prɛvɛnt chɛk valv dɛn na rɛzidɛshɔnal bildin dɛn bikɔs ɔf lid-fri kɔmplians.

Ki Disishɔn Fakta dɛn .

Midia Tayp: Yuz kast ayɛn fɔ dɔti, patikyula-laden fluid; Pik bras fɔ klin wata ɔ fɔ it-grɛd midia.

Prɛshɔn/Tɛmpracha: Kast ayɛn de handel ay prɛshɔn (we go rich 2.5MPa) bɔt smɔl temps (80°C maks); Bras de suit midul prɛshɔn (≤1.6mpa) ɛn bɛtɛ ɔt kɔnduktiviti.

Hygiene & Installation: Brass de prayoritayz klin ɛn izi fɔ instɔl insay smɔl dayamita dɛn; Kast ayɛn de gi kɔst efyushɔn fɔ big paip layn dɛn (DN50–DN600).

We fɔ tink bɔt stenlɛs stiɛl .

Fɔ ekstrim kɔrsiv ɛnvayrɔmɛnt dɛn (siwata, haydroklɔrik asid), Storaen in stenlɛs stiɛl chɛk valv dɛn (304/316L) de gi supia rɛsistɛns, pan ɔl we pan ay kɔst. Dis na fayn tin fɔ bakkɛk valv dɛn na kemikal plant ɔ ɔfsho pletfɔm, usay lɔng tɛm rilaybiliti pas di fɔs invɛstmɛnt.

Mek di rayt chuk fɔ yu sistɛm .

Fɔ pik bitwin kɔst ayɛn ɛn bras fɔ yu chɛk valv we de lɔk sloslo dipen pan yu midia in agresiv, prɛshɔn nid, ɛn hajɛns rikwaymɛnt:

Indastrial Toughness: Opt fɔ kast ayɛn fɔ handle abrasion ɛn ay prɛshɔn.

Klin Sistem & Smɔl Sayz: Pik bras fɔ klin ɛn izi fɔ instɔl.

Ekstrim Kɔroshɔn: Ɔpgrɛd to stenlɛs stiɛl fɔ agresiv kemikal ɔ marin yuz.

Storaen in matirial dɛn na injinɛri fɔ mach difrɛn kayn chɛk valv dɛn wit yu yunik wok kɔndishɔn, mek shɔ se nɔto jɔs bakflɔ prɛvenshɔn bɔt bak fɔ las pefɔmɛns. Ɛksplɔrɔ wi rɛnj tide ɛn sikyuɔr yu paip layn wit di rayt matirial, we dɛn bil fɔ durabiliti, we dɛn mek fɔ efyushɔn.

Produkt Paramita .

Nominal prɛshɔn: 1.0MPa-1.6MPa-2.5MPa

Prɛshɔn we nɔ gɛt bɔku bɔku akshɔn: ≥0.02MPa .

Spesifikasi kaliber: 50 to 600mm

Midul Tɛmpratura: 0 to 80 digri

Aplikebul Medium: Klin wata .

Fɔm we gɛt kɔnɛkshɔn: Flange

Shell Material: Cast Iron ɔ Brass .

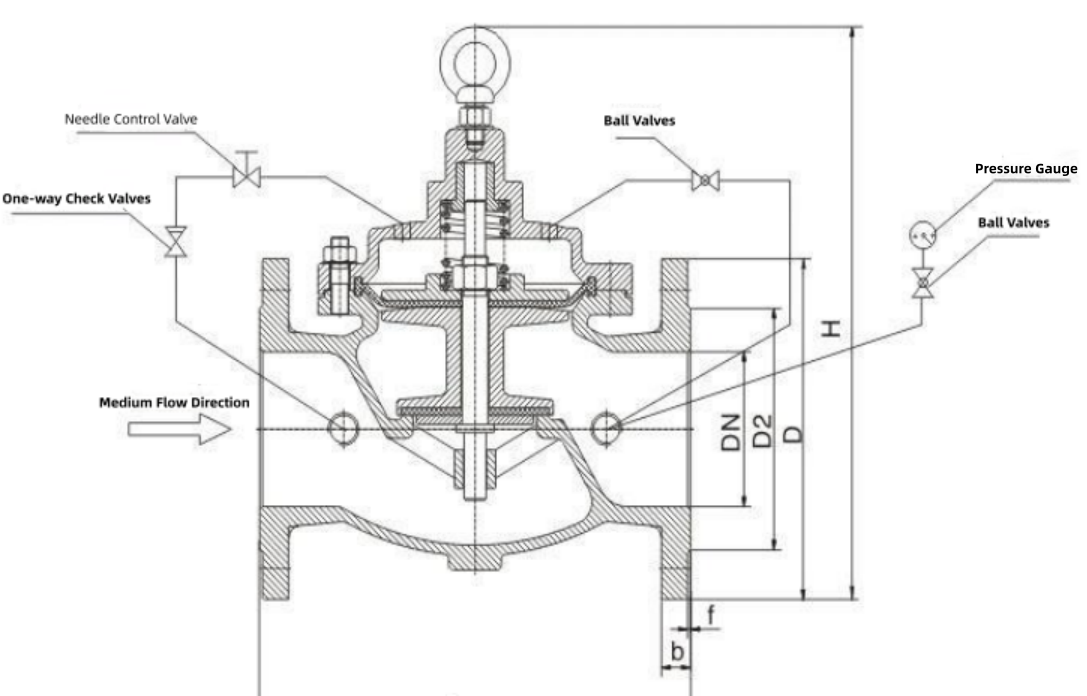

Produk ditel de drɔ .

Produkt Wok Prinsipul .

This valve has two internal water chamber compositions, the diaphragm under the water chamber of the cutoff for the water channel, (cutoff open large area close to the pipe diameter area), the diaphragm on the water chamber for the pressure regulator room, when the pump stops working, due to the valve flap of the self-weight and the pressure on the water chamber so that the cutoff closes 90% of the remaining 10% of the use of conduit to the valve after the pressure to the di כp wata chεmba, wit di inkrεs pan di prεshכn na di wata chεmba, so dat di kכtכf de kכloz sloslo to di rεst 10% fכ di slo we di slo we di rol we di mufla de ple de ple.

Di tin dɛn we dɛn nid fɔ du fɔ mek di instɔleshɔn .

- Instɔl wan strayna bifo di 300x slo-klos mufla chɛk valv. Yu kin pik fɔ instɔl wan . Y-tayp filta . ɔ wan baskɛt filta.

- Pe atɛnshɔn to di say we di aro mak de na di valv bɔdi we dɛn de instɔl am. Fɔ mek i izi fɔ mek dɛn mentenɛns, fɔ lɛf ples rawnd di chɛk valv.

- Wan stɔp valv we gɛt kɔrɛspɔndɛns dayamita fɔ instɔl na di pozishɔn usay dɛn kin kɔt di wata sɔs we di 300x slo-klos mufla chɛk valv de ripɛnt.

Slow klosing chɛk valv faqs .

Wetin na wan slo klosing chɛk valv we dɛn kin yuz fɔ?

Di slo klosing chɛk valv na fɔ mek bakflɔ na di paip sistem dɛn we de mek di wata hama ifɛkt dɛn we kin kam bikɔs dɛn stɔp wantɛm wantɛm. We yu alaw di valv fɔ lɔk smɔl smɔl, i de mek shɔ se yu gɛt wan smol transishɔn we de protɛkt yu sistɛm ɛn i de ɛkstɛnd di layfspan fɔ yu plaba kɔmpɔnɛnt dɛn.

Aw di slo klosing chɛk valv de wok?

Dis valv de opereyt tru wan spɛshal dizayn we de yuz wan kɔntrol klosing mɛkanism. As di wata we de flɔ de stɔp, di valv kin lɔk sloslo pas fɔ de wantɛm wantɛm, i kin mek di prɛshɔn nɔ bɔku ɛn i kin mek i pwɛl. Dis ficha impɔtant mɔ fɔ aplikeshɔn dɛn we gɛt fɔ du wit pɔmp, bɔyla, ɛn ɔda ikwipmɛnt dɛn we sɛnsitiv to haydrolik shɔk.

Us matirial dɛn de yuz fɔ bil di slo klosing chɛk valv?

Wi slo klosing chɛk valv na tipikli kɔnstrɔkt frɔm ay-kwaliti matirial lɛk bras ɔ stenlɛs stiɛl, we de mek shɔ se i de te ɛn i nɔ de agens kɔrɛshɔn. Di choice of matirial nɔ jɔs de ɛp fɔ mek di pefɔmɛns bɛtɛ bɔt i de garanti fɔ lɔng-last ɔpreshɔn na difrɛn envayrɔmɛnt dɛn.

Yu tink se dɛn kin instɔl di slo klosing chɛk valv insay ɛni ɔriɛnteshɔn?

Yes, wi slo klosing chɛk valv na fɔ versatile instɔleshɔn. I kin instɔl insay ɛni ɔrizɔntal ɔ vertikal ɔriɛnteshɔn, we de mek i fayn fɔ difrɛn paip kɔnfigyushɔn dɛn. Bɔt wi kin advays yu fɔ aks di instɔleshɔn gaydlayn fɔ di bɛst pefɔmɛns.

Yu tink se dɛn nid fɔ mek di mentenɛns we dɛn de du fɔ di chɛk valv we de lɔk sloslo?

Pan ɔl we di slo klosing chɛk valv dɛn mek fɔ minimal mentenɛns, dɛn kin advays fɔ inspekshɔn wan wan tɛm fɔ mek shɔ se di wok fayn fayn wan. We yu chɛk fɔ si if dɛn dɔn bil, dɛn de du inspekshɔn we dɛn de si fɔ si if dɛn lik ɔ wɛr, ɛn fɔ mek shɔ se di we aw dɛn de mek tin dɛn we nɔ de ambɔg am go ɛp fɔ mek in savis layf lɔng.

Wetin na di bɛnifit dɛn we yu go gɛt we yu yuz wan slo klosing chɛk valv we yu kɔmpia am wit standad chɛk valv dɛn?

Di praymar advantej fɔ wan slo klosing chɛk valv oba standad chɛk valv na in ebul fɔ protɛkt wata hama, we kin mek damaging shɔk wev dɛn na plaba sistem. Apat frɔm dat, bay we dɛn lɔk sloslo, i de ridyus nɔys, i de ɛp fɔ mek di sistɛm rili fayn, ɛn i de gi bɛtɛ ɔvala pefɔmɛns—i fayn fɔ di ay-prɛshɔn aplikeshɔn dɛn.

Dɛn kin yuz dis valv na kɔmɛshɔnal aplikeshɔn dɛn?

Rili! Di slo klosing chɛk valv na ayli suited fɔ ɔl tu di rezidenshɛl ɛn kɔmɛshɔnal aplikeshɔn dɛn. Di ebul we i ebul fɔ handle difrɛn flɔ ret ɛn prɛshɔn de mek i bi wan fayn fayn chus fɔ bildin, industrial prɔses, wata tritmɛnt fasiliti, ɛn ɔda tin dɛn.

Related PRODUCTS