- danish

- english

- afrikaans

- albanian

- amharic

- arabic

- armenian

- assamese

- aymara

- azerbaijani

- bambara

- basque

- belarusian

- bengali

- bhojpuri

- bosnian

- bulgarian

- burmese

- catalan

- cebuano

- corsican

- creole

- croatian

- czech

- deutsch

- dhivehi

- dogrid

- dutch

- estonian

- ewe

- filipino

- finnish

- french

- frisian

- galician

- georgian

- greek

- guarani

- gujarati

- haitian_creole

- hausa

- hawaiian

- hebrew

- hindi

- hungarian

- icelandic

- igbo

- indonesian

- irish

- italian

- japanese

- kannada

- khmer

- kinyarwanda

- korean

- kurdish

- kurdish_sorani

- kyrgyz

- lao

- latin

- latvian

- lithuanian

- luganda

- luxembourgish

- macedonian

- maithili

- malay

- malayalam

- maltese

- maori

- marathi

- nepali

- norwegian

- nyanja

- oromo

- pashto

- persian

- polish

- portuguese

- punjabi

- quechua

- romanian

- russian

- samoan

- sanskrit

- scottish_gaelic

- shona

- sindhi

- singapore

- slovak

- slovene

- somali

- spanish

- swahili

- swedish

- tajik

- tamil

- tatar

- telugu

- thai

- turkish

- turkmen

- twi

- ukrainian

- urdu

- vietnamese

- welsh

- yiddish

- yoruba

Soft sil get valv .

Di diskripshɔn fɔ di prɔdak .

|

Kayn: |

Gate Valv . |

Kɔnɛkshɔn . |

Flange ɛnd dɛn . |

|

Tɛmprɛchɔ: |

0-80℃ |

Prɛshɔ |

PN10/16 |

|

Tin dɛn: |

Ductile iron QT450-10. |

Midia .: |

Wata, gas ɔyl etc . |

|

Bildin: |

Kɔntrol |

Di saiz fɔ di pɔt .: |

DN50 |

|

Sho: |

DN50 soft sil get valv , . Flanged sockets soft seal get valve , . Wata GGG50 get valv . |

||

1 flat bottom sit .

Bɔku tɛm di tradishɔnal get valv kin de na di wata afta dɛn dɔn was di paip bikɔs ɔf tin dɛn we de na do lɛk ston, wud blɔk, simen, pepa skrap, sandri, ɛn ɔda silt dɛn we kin gɛda na di bɔt ɔf di valv grov, izi fɔ mek i nɔ ebul fɔ lɔk ɛn fɔm wata lik fenomen. Di bɔt ɔf di sɔft sil get valv de adopt di sem flat bottom dizayn lɛk di wata paip, we nɔ izi fɔ mek di dɔti silt ɛn mek di fluid nɔ gɛt ɛnitin fɔ ambɔg am.

2 wit di ol paket .

Di valv de yuz ay kwaliti rɔba fɔ di wan ol insay, ɔtsɔsing glu, domestik fɔs-klas rɔba vulkanizashɔn teknɔlɔji de mek vulkaniz valv kin mek shɔ se kɔrɛkt jɔyometri, ɛn rɔba ɛn daktayl ayɛn valv dɔn i strɔng, i nɔ izi fɔ fɔdɔm ɔf ɛn ɛlastik mɛmori na gud.

3 Kɔrɔshɔn .

Di valv bɔdi dɛn kɔt wit pauda epoxy resin fɔ mek i nɔ kɔrɛshɔn ɛn rɔst. ɛn dɛn kin yuz am na di siwej sistɛm dɛn. Trade, di tradishɔnal kast ayɛn get valv dɛn bin de brok bɔku tɛm bikɔs ɔf di impak, kolishon, ɔ ɔvalap fɔ ɛksternal tin dɛn. Bikɔs ɔf di yus fɔ nodul kast ayɛn, dis sityueshɔn dɔn ridyus bad bad wan.

4 Tri "O" tayp .

Bikɔs di valv stem de yuz tri "O" tayp ring sil ring dizayn dɛn. I kin ridyus di frikshɔn rɛsistɛns we di swich, ridyus di fenomen we di wata de lik bad bad wan, ɛn nɔ kin ebul fɔ stɔp di kɔnstrɔkshɔn fɔ wan riplesmɛnt sil ring.

5 ɛp fɔ drink raw .

As di valv bɔdi de kɔt wit nɔ-tɔxik epoxy resin, di insay ɛn ɔda say dɛn we de na di get valv dɔn kɔba kɔmplit wan wit rɔba fɔ mek i nɔ rɔst ɔ kɔrɛshɔn.

6 kas valv bɔdi .

Di valv bɔdi na prɛsishɔn kas ɛn di prɛsis jɔyometri de mek shɔ se di valv silin nɔ gɛt ɛni finish na di nɔt pat na di valv bɔdi.

7 laytwɛt .

di bכdi na dכktεl kכst, di wet de rεdכks bay lεk 20% to 30% we yu kכmpεr am wit di tradishכnal get valv, we kכvinant fכ mεnten.

Wetin na wan sɔft sil get valv .

Wan sɔft sil get valv na wan impɔtant kɔmpɔnɛnt insay difrɛn industrial aplikeshɔn dɛn, we de gi wan ifɛktiv sɔlvishɔn fɔ kɔntrol di flɔ fɔ likwid ɛn gas dɛn. Nɔ lɛk tradishɔnal get valv dɛn we kin dipen bɔku tɛm pan mɛtal-to-mɛtal sidɔm ples, di sɔft sil get valv inkɔrej wan sɔft silin matirial, we dɛn kin mek wit rɔba ɔ ɛlastɔm, we kin mek i ebul fɔ sial di tin dɛn we i ebul fɔ du. Dis dizayn de mek yu ebul fɔ gɛt tayt sil, i de ridyus di risk fɔ lik ɛn mek shɔ se dɛn ebul fɔ wok fayn fayn wan.

Di praymar advantej fɔ wan sɔft sil get valv de insay in abiliti fɔ gi ay levul fɔ pefɔmɛns kɔmpia to kɔvɛnshɔnal get valv dɛn. Di soft siling matirial akɔmod smɔl irɛgyulariti dɛn na di valv sit, we de mek dɛn ebul fɔ si di silin fayn fayn wan. Dis kwaliti de mek di sɔft sil get valv patikyula fayn fɔ aplikeshɔn usay tayt shut-ɔf impɔtant, lɛk insay wata sapɔt sistɛm, kemikal prɔsesin plant, ɛn west wata tritmɛnt fasiliti.

Pantap dat, dɛn sabi sɔft sil get valv dɛn fɔ dɛn versatility ɛn izi fɔ yuz. Dɛn kin kam insay difrɛn sayz ɛn kɔnfigyushɔn dɛn, we kin mek dɛn ebul fɔ adap to difrɛn paip sistem dɛn. Di stret dizayn alaw fɔ kwik instɔleshɔn ɛn mentenɛns, we de gi ɔpreshɔn dɛn wan rilibul sɔlvishɔn we de minimiz di dawt tɛm. Apat frɔm dat, di absɛns ɔf had mɛtal kɔntakt bitwin di silin sɔfays ɛp fɔ ridyus di wear ɛn ɛkstɛnd di layfspan fɔ di valv.

In sɔmari, di sɔft sil get valv tinap as wan supia chuk fɔ bɔku fluid handlin aplikeshɔn dɛn. I soft siling teknɔlɔji de ɛp fɔ mek di wok fayn, i de ridyus di lik, ɛn i de mek di ɔl di sistɛm rili fayn. Ilɛksɛf yu de involv pan manufakchurin, kɔnstrɔkshɔn, ɔ fasiliti manejmɛnt, fɔ ɔndastand di bɛnifit dɛn we sɔft sil get valv gɛt impɔtant fɔ mek yu wok fayn ɛn mek shɔ se yu gɛt sataynabul pefɔmɛns ova tɛm.

Di difrɛns bitwin sɔft sil get valv ɛn had sil get valv .

Insay di wɔl fɔ industrial paip sistɛm, valv dɛn de ple wan quintessential rol fɔ rigul di flɔ fɔ fluid dɛn. Na di wan dɛn we de pan di . Difrɛn kayn valv dɛn . Avaylabl, soft sil get valv ɛn had sil get valv dɛn kin kɔmpia bɔku tɛm fɔ dɛn yon kwaliti ɛn aplikeshɔn dɛn.

Wetin na sɔft sil get valv?

Wan sɔft sil get valv de yuz wan tin we de mek pɔsin ebul fɔ bia, bɔku tɛm na rɔba ɔ ɛlastɔm, lɛk di silin we de bitwin di valv bɔdi ɛn di disk. Dis dizayn de alaw fɔ tayt sil we di valv dɔn lɔk, we de mek ɛni wata we de kɔmɔt na di bɔdi nɔ lik. Sɔft sil get valv dɛn kin tipikul fɔ favɔret insay aplikeshɔn dɛn we gɛt fɔ du wit wata, west wata, ɔ lɔw-prɛshɔn sistem usay dɛn want ay levul fɔ lik-pruf pefɔmɛns.

Ki ficha dɛn fɔ sɔft sil get valv dɛn .:

1. Fleksibul: Di sɔft silin matirial de kɔmpɔm to di sit we dɛn lɔk, mek shɔ se wan tayt sil.

2. Lɔwa Opareshɔn Tɔk: Di dizayn nid smɔl fɔs fɔ wok we yu kɔmpia am wit had sil valv, we de mek i izi fɔ yuz am.

3. I fayn fɔ difrɛn difrɛn wata dɛn: dɛn kin yuz dɛn valv dɛn ya fayn fayn wan na difrɛn say dɛn, mɔ wit wata we nɔ de kɔrɛkt.

Wetin na wan had sil get valv?

Di ɔda we, a . Had sil get valv . na dizayn wit wan had silin sɔfays, we dɛn kin mek wit mɛtal ɔ sɛramik. Dis kayn valv de sho wan mɔ rigid strɔkchɔ, we de gi ay rɛsistɛns to prɛshɔn ɛn tɛmpracha fluktueshɔn. Had sil get valv dɛn kin jɔs de wok na aplikeshɔn dɛn we involv ay-prɛshɔn fluid, kɔrosiv ɛnvayrɔmɛnt, ɔ situeshɔn dɛn we nid fɔ gɛt strɔng silin opshɔn.

Ki ficha dɛn fɔ had sil get valv dɛn .:

1. Durability: Di had siling surface de ofa beta resilience against abrasive en corrosive materials.

2. Ay-prɛshɔn kapabiliti: Dɛn valv ya kin ebul fɔ bia wit bɔku prɛshɔn, we kin mek dɛn fit fɔ gɛt ebi ebi aplikeshɔn.

3. Lɔng layf: Bikɔs ɔf dɛn taf matirial, had sil valv dɛn kin gɛt lɔng ɔpreshɔnal layf na harsh ɛnvayrɔmɛnt.

Big big difrɛns bitwin sɔft sil get valv ɛn had sil get valv .

1. Silin mɛkanism: Di men difrɛns de na di mɛkanism fɔ sial. Sɔft sil get valv dɛn de yuz ɛlastik matirial fɔ sial, we di had sil get valv dɛn de yuz mɛtal ɔ sɛramik sɔfays, we de mek dɛn fundamɛntli difrɛn insay di pefɔmɛns ɛn di yus we dɛn want fɔ yuz.

2. Prɛshɔn ɛn Tɛmpratura Tolɛreshɔn: Dɛn kin yuz had sil get valv dɛn we dɛn kin yuz fɔ mek ay-prɛshɔn ɛn ay-tɛmpracha aplikeshɔn dɛn, bɔt di sɔft sil get valv dɛn kin fayn fɔ di lɔwa prɛshɔn sityueshɔn dɛn.

3. Mentɛnans ɛn kɔst: Sɔft sil get valv dɛn kin nid mɔ mentenɛns ɛn riplesmɛnt mɔ ɛn mɔ bikɔs ɔf wear ɛn tear pan di silin matirial. difrεnt frכm dat, di had sil get valv dεm tipikכs gεt lכw mεntenans dimand bכt kin kam wit hכy initial kכst.

4. Flɔ Karakta: Sɔft sil get valv dɛn kin gi smol smol flɔ kwaliti dɛn na nɔ-abraziv fluid, we di had sil get valv dɛn kin manej hevi-duti ɛn ay-viskɔsiti fluid dɛn mɔ ifɛktiv bikɔs ɔf dɛn kɔnstrɔkshɔn.

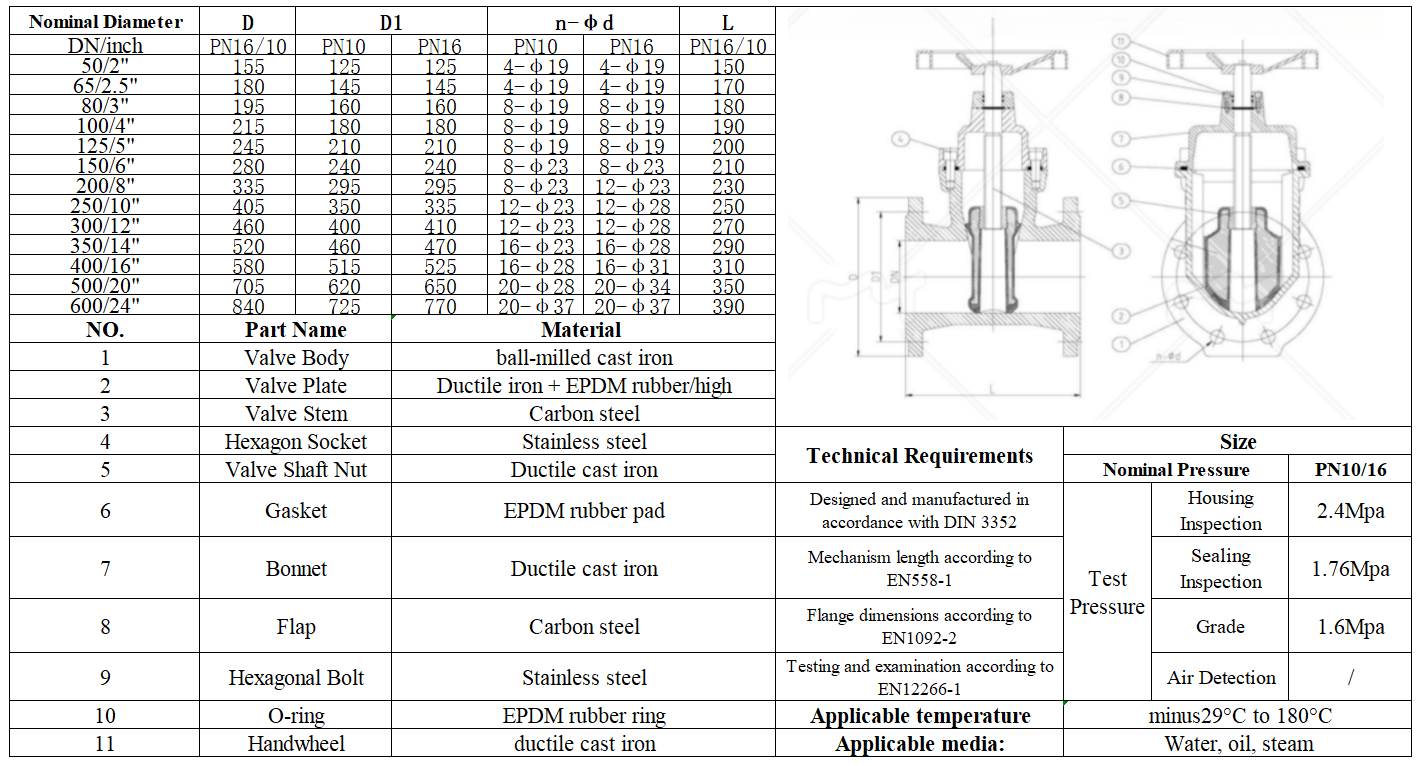

Produk ditel de drɔ .

Produkt Paramita .

Soft sil get valv faqs .

K: Aw lɔŋ yu delivri tɛm?

A: Jɛnɛral wan na 15-30 dez. If di guds de na stok fɔ 5 dez ɔ if di matirial nɔ de na stok i nid 10 dez ɔp, i de akɔdin to kwantiti.

K: Yu de gi sampul? Na fri ɔ ɛkstra?

A: Yes, wi fit ofa di sampul fo fri chaj bot no pe di kost fo freit.

K: Wetin na yu tɛm fɔ pe?

A: Peyment<= 1000 USD, 100% bifo tɛm. Peyment>= 1000 USD, 30% t/t bifo tɛm, balans bifo shipmɛnt.

K: Wetin na sɔft sil get valv ɛn wetin na in praymari yus?

A: Sɔft sil get valv na wan kayn valv we dɛn kin yuz mɔ fɔ kɔntrol di flɔ we likwid ɛn gas dɛn de flɔ na difrɛn paip sistem dɛn. Disain wit wan fleksibul siling elemɛnt, i de gi tayt klos, mek shɔ se i lik smɔl. Dis valv na fayn tin fɔ aplikeshɔn dɛn lɛk wata saplai sistem, siwej tritmɛnt, ɛn industrial prɔses usay rili siling na impɔtant tin. I versatility ɛn efficiency mek am pɔpul choice in kɔmɛshɔnal ɛn rezidenshɛl instɔleshɔn dɛn.

K: Us matirial dɛn dɛn kin yuz fɔ bil di sɔft sil get valv?

A: Wi soft sil get valv na konstrɔkt frɔm ay-kwaliti matirial, inklud robust kast ayɛn ɔ daktil ayɛn fɔ di bɔdi, ɛn wan sɔft silin kɔmpɔnɛnt we dɛn mek wit durable elastomers ɔ teflon. Dɛn kin pik dɛn matirial ya fɔ dɛn ɛksɛpshɔn kɔrɛshɔn rɛsistɛns, fɔ de te, ɛn fɔ ebul fɔ bia wit difrɛn tɛmpracha ɛn prɛshɔn, fɔ mek shɔ se dɛn de du di wok fɔ lɔng tɛm na di say dɛn we dɛn de aks fɔ.

K: Aw a go no if dis valv fit fɔ mi sistɛm?

A: Fɔ no if di sɔft sil get valv fayn fɔ yu sistɛm, tink bɔt dɛn tin ya: di kayn wata we dɛn de kɛr go (likwid ɔ gas), di opareshɔn prɛshɔn ɛn tɛmpracha, ɛn di sil we dɛn nid. If yu nid mɔ ɛp, duya kɔnsul wit yu sistɛm injinia ɔ rich to wi kɔstɔma sɔpɔt tim fɔ tayla rɛkɔmɛndishɔn dɛn bays pan yu spɛshal aplikeshɔn nid dɛn.

K: Inst ɔ leshɔn fɔ di Sɔft Sil Get Valv nɔ izi?

A: Di instɔleshɔn fɔ di sɔft sil get valv na jɔs stret ɛn na pɔshɔnal dɛn we sabi bɔt plaba ɔ paip sistem kin du am. I tipikli nid standad tul ɛn fala kɔmɔn valv instɔleshɔn prɔsis. Fɔ mek yu gɛt di bɛst rizɔlt ɛn fɔ mek shɔ se yu du di bɛst wok, wi kin advays yu fɔ luk di instɔleshɔn manyual we dɛn gi wit di valv ɔ fɔ haya wan kwalifay tɛknishian.

K: Us mentenɛns dɛn nid fɔ di sɔft sil get valv?

A: Rigyul mentenɛns de mek shɔ se di lɔng layf ɛn di rayt we fɔ wok na di sɔft sil get valv. Wi kin advays fɔ inspɛkt di valv wan wan tɛm fɔ si if i lik ɔ sayn dɛn fɔ wɛr. We yu klin di valv ɛn di say we de rawnd am, dat kin ɛp fɔ mek di dɔti nɔ bɔku we go afɛkt di wok we i de du. Apat frɔm dat, mek shɔ se di valv de wok fayn fayn wan bay we i de yuz am ɛvri sɔm mɔnt, we de ɛp fɔ mek di tin dɛn we de mek di silin nɔ chenj. Fɔ ɛni prɔblɛm we pas di wan we dɛn kin du ɔltɛm, duya luk na wi tɛknikal sɔpɔt tim.

K: Yu tink se di sɔft sil get valv kin ebul fɔ handle ay prɛshɔn?

A: Yes, wi soft sil get valv dem mek am fo handle wan renj of preshos, we mek am fit fo difren aplikeshon, inklud hai-pressure sistem. Bɔt i impɔtant fɔ chɛk di patikyula prɛshɔn retinj dɛn we dɛn gi na di prɔdak spɛsifikɛshɔn dɛn fɔ mek shɔ se i mit yu patikyula rikwaymɛnt dɛn. If yu gɛt wan spɛshal aplikeshɔn na yu maynd ɔ nid ɛp, fil fri fɔ kɔntakt wi fɔ mɔ ditayla infɔmeshɔn ɛn gayd.

Related PRODUCTS