Plɔg gej dɛn na indispɛnsabl tul dɛn na prɛsishɔn injinɛri, we de gi akchualiti ɛn rilaybiliti we nɔ gɛt wan kɔmpitishɔn fɔ inspɛkt di dimɛnshɔn dɛn fɔ ol ɛn bor dɛn. If dɛn sɔs frɔm trɔst spɔlayt dɛn we de gi plɔg gej fɔ sɛl ɔ kɔstɔm-dizayn bay wan reputed snap gej manifakta, dɛn inschrumɛnt ya de mek shɔ se kɔmpɔnɛnt dɛn mit strikt tolɛreshɔn, wan impɔtant rikwaymɛnt insay industri dɛn lɛk ɔtomotiv, aerospace, ɛn manufakchurin. Wan plein plɔg gej na patikyula valyu fɔ mɛzhɔ di intanɛnt dayamita dɛn fɔ mashin pat dɛn, we de gi wan stret pas/fayl rizɔlt we de pul ambiguiti ɛn mek shɔ se i gɛt fayn kwaliti kɔntrol. Dɛn strɔng kɔnstrɔkshɔn ɛn prɛsis kalibreshɔn de mek dɛn fayn fɔ yuz ay-ripitishɔn, ridyus wear ɛn tea we dɛn de mentɛn akkuracy ova tɛm. Apat frɔm dat, plɔg gej dɛn strimlayn inspekshɔn prɔses, we de alaw di manifakta dɛn fɔ ajɔst fasta prodakshɔn saykl dɛn we nɔ go kɔmprɔmis prɛsishɔn. We dɛn jɔyn rilaybiliti, durabiliti, ɛn izi fɔ yuz, plɔg gej dɛn na sɔntin we pɔsin fɔ gɛt fɔ ɛni ɔpreshɔn we de aim fɔ sɔpɔt strɔng kwaliti standad dɛn na prodakshɔn.

Tayp dɛn fɔ plɔg gej .

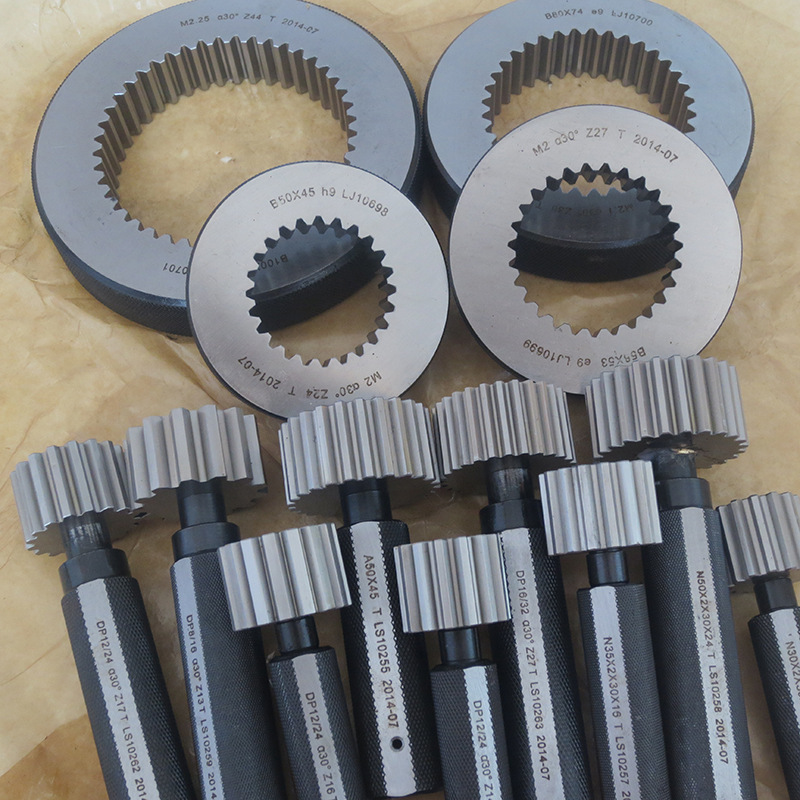

Plɔg gej fɔ sɛl kam insay difrɛn kayn dɛn, ɛni wan tayla to spɛshal mɛzhɔmɛnt nid, mek shɔ se prɛsishɔn insay difrɛn industrial aplikeshɔn dɛn. Di kayn we dɛn kin kɔmɔn pas ɔl na plein plɔg gej dɛn, taper plɔg gej dɛn, trɛd plɔg gej dɛn, ɛn go/nɔ-go plɔg gej dɛn, ɛni wan pan dɛn de gi difrɛn tin dɛn we dɛn de du fɔ kɔntrol kwaliti ɛn dimɛnshɔnal inspekshɔn.

Plɛn plɔg gej dɛn kin yuz bɔku bɔku wan fɔ mɛzhɔ di insay dayamita dɛn fɔ smol, silinda ol dɛn. Dɛn kin stret, dɛn kin gi ɛni wan pan di pas ɔ di fayl autkam, mek shɔ se di kɔmpɔnɛnt dɛn mit di tolɛreshɔn dɛn we dɛn nid. Dɛn gej ya na fayn tin fɔ jenɛral-pɔpɔs aplikeshɔn dɛn, mɔ na di ɔtomotiv ɛn manufakchurin sɛktɔ dɛn.

Taper plɔg gej dɛn na spɛshal wan fɔ mɛzhɔ tapered ol dɛn, we dɛn kin fɛn insay aplikeshɔn dɛn we nid prɛsishɔn alaynɛshɔn ɔ fitin. Dɛn gej ya de mek shɔ se di taper angle ɛn dimɛnshɔn dɛn de kɔnfɔm to dizayn spɛsifikɛshɔn dɛn, we impɔtant na eria dɛn lɛk paip fitin ɛn fluid mɛkaniks.

trɛd plɔg gej dɛn impɔtant fɔ chɛk di akkuracy fɔ intanɛnt trɛd dɛn na nɛt, bush, ɛn ɔda tin dɛn we tan lɛk dɛn. Dɛn kam insay tu pat: di "go" sayd verify se di trɛd de insay maksimam tolɛreshɔn, we di "nɔ-go" sayd de mek shɔ se i nɔ pas di minim tolɛreshɔn.

Go/no-go plɔg gej dɛn na versatil tul dɛn we de kam togɛda tu gej dɛn insay wan. Di "go" ɛnd de chɛk if di ol mit di minim akseptabl dimɛnshɔn, ɛn di "nɔ-go" ɛnd de mek shɔ se i nɔ pas di maksimam. Dis dual functionality de mek inspekshɔn dɛn simpul ɛn impruv efyushɔn.

Dɛn difrɛn kayn plɔg gej ya, we dɛn kin gɛt frɔm spɛshal Stɔ Snap gej manifakta dɛn, de mek dɛn ebul fɔ mɛzhɔ di rayt ɛn rili fayn akɔdin to di industri dɛn, we de mek shɔ se dɛn gɛt kɔnsistɛns kwaliti ɛn dɛn de fala di spɛsifikɛshɔn dɛn. Fɔ pik di rayt plɔg gej dipen pan di patikyula aplikeshɔn, matirial, ɛn di lɛvɛl we di prɛsishɔn nid.

Taper gej funkshɔn .

Taper gauge na prɛsishɔn tul we dɛn kin yuz fɔ mɛzhɔ di dimɛnshɔn dɛn fɔ tapered spɛs, gap, ɔ intanɛnt bor dɛn na mɛkanikal kɔmpɔnɛnt dɛn. I valyu mɔ fɔ di ebul we i ebul fɔ gi kɔrɛkt ridin dɛn na sɛnɛriɔ usay kɔvɛnshɔnal gej ɔ kalipa dɛn kin strɛs. di praymar fכnshכn fכ wan taper gεj na fכ ases di wit כ dayamita fכ wan tεp, we tipikכs de frכm narכ to wida εnd dεm. Dis na impɔtant tin na industri dɛm lɛk mashin, ɔtomotiv, ɛn manufakchurin, usay prɛsis taper mɛzhɔmɛnt nid fɔ mek shɔ se di kɔmpɔnɛnt dɛn fit togɛda seamles ɔ ɔpreshɔn fayn fayn wan.

Taper gej dɛn kin rili yusful fɔ no di dip we di grov dɛn dip ɔ di kliarens na di smɔl smɔl gap dɛn. Fɔ ɛgzampul, insay asɛmbli wok ɔ mentenɛns, dɛn kin ɛp fɔ chɛk fɔ si if wan pat we gɛt tap, lɛk wan kɔn-shep bor ɔ spindle, de mach in mating kɔmpɔnɛnt, we de ridyus di risk fɔ mek dɛn nɔ gi di pɔsin di rayt we ɔ we i nɔ de wok fayn. Di gej in tapered bled ɔ dizayn de alaw am fɔ slayv fayn fayn wan insay di eria we dɛn mɛzhɔ, we de gi wan kwik ɛn rili we fɔ chɛk tolɛreshɔn.

Apat frɔm dɛn prɛktikal mɛzhɔmɛnt aplikeshɔn dɛn, taper gej dɛn impɔtant fɔ kwaliti kɔntrol prɔses. Dɛn de mek shɔ se dɛn kɔnsistɛns fɔ mek pat dɛn wit prɛsis tapa dɛn, we de ɛp biznɛs dɛn fɔ kɔntinyu fɔ gɛt ay kwaliti standad. Dɛn gej ya bak kin yuz fayn fayn wan, dɛn kin nid fɔ gɛt smɔl trenin, ɛn dɛn kin mek tin dɛn we go de fɔ lɔng tɛm lɛk stenlɛs stiɛl fɔ bia wit ebi ebi industri. Ultimately, di taper gauge in funkshɔn go biyɔn simpul mɛzhɔmɛnt; I de ple wan impɔtant pat fɔ mek dɛn ebul fɔ du di wok fayn fayn wan, di sef, ɛn di lɔng layf we di mashin dɛn we dɛn mek wit mashin gɛt.

Wetin na di plɔg gej we dɛn kin yuz fɔ?

Insay di eria fɔ industrial manufakchurin ɛn kwaliti kɔntrol, prɛsishɔn na di men tin. Wan pan di impɔtant tin dɛn we dɛn yuz fɔ mek shɔ se di dimɛnshɔn dɛn kɔrɛkt na di plɔg gej. Dis spɛshal mɛzhɔmɛnt inschrumɛnt de sav wan impɔtant wok fɔ asɛs di sayz ɛn tolɛreshɔn dɛn fɔ ol ɛn opin dɛn na difrɛn kɔmpɔnɛnt dɛn.

Wan plɔg gej na in dɛn kin yuz mɔ fɔ chɛk di intanɛnt dimɛnshɔn dɛn fɔ di ol dɛn fɔ kɔnfɔm if dɛn mit spɛsifikɛd tolɛreshɔn dɛn. I kin jɔs kam insay tu vayriet dɛn: di go gej ɛn di no-go gej. Di go gej na fɔ fit insay di ol, we de sho se di ol in dimɛnshɔn dɛn na akseptabl. Di ɔda we, di no-go gej min fɔ nɔ fit insay di ol; If i du dat, i de sho se di ol nɔ de fɔgiv. Dis dual funkshɔn de alaw kwaliti kɔntrol inspɛkta dɛn fɔ no kwik kwik wan if pat dɛn de adara to injinɛri spɛsifikɛshɔn dɛn.

Dɛn mek plɔg gej dɛn wit ay kwaliti, tin dɛn we go de fɔ lɔng tɛm fɔ mek shɔ se dɛn liv lɔng ɛn kɔrɛkt as tɛm de go. Dɛn na fayn fayn wan mashin ɛn kalibrayt, we de alaw fɔ minimal chenj na mɛzhɔmɛnt, we impɔtant fɔ mek dɛn kɔntinyu fɔ kɔnsistɛns akɔdin to di prodakshɔn prɔses. Di industri dɛm we kin yuz plɔg gej dɛm bɔku tɛm na aerospace, ɔtomotiv, ɛn mashin manufakchurin, usay prɛsis mɛzhɔmɛnt kin rili impɔk di pefɔmɛns ɛn sef fɔ di prɔdak dɛm.

Fɔ sɔma, di plɔg gej na wan indispɛnsabl tul fɔ kwaliti ɛshyurishɔn na di manufakchurin sɛktɔ. Bay we i de mek dɛn ebul fɔ mɛzhɔ di intanɛnt dimɛnshɔn dɛn kɔrɛkt wan, i de ple wan impɔtant pat fɔ mek shɔ se di kɔmpɔnɛnt dɛn fit togɛda lɛk aw dɛn dɔn disayd. Ilɛksɛf na big big prodakshɔn ɛnvayrɔmɛnt ɔ smɔl wokshɔp, fɔ ɔndastand ɛn yuz plɔg gej dɛn fayn fayn wan kin mek dɛn impɔtant impɔtant tin dɛn fɔ mek di prɔdak kwaliti ɛn fɔ mek dɛn wok fayn fayn wan. Fɔ ɛnibɔdi we de wok fɔ mek, fɔ masta di yus fɔ plɔg gej na wan impɔtant skil we de mek shɔ se dɛn de fala di ay standad fɔ ɛksɛlɛns.

Wetin na di difrɛns bitwin plɔg gej ɛn pin gej?

Plɔg gej ɛn pin gej na ɔl tu prɛsishɔn mɛzhɔmɛnt tul dɛn, bɔt dɛn de sav difrɛn tin dɛn ɛn dɛn difrɛn pan dizayn, aplikeshɔn, ɛn funkshɔnaliti. Fɔ ɔndastand dɛn difrɛns ya impɔtant fɔ pik di rayt tul fɔ wan patikyula inspekshɔn wok.

Plɔg gej .:

Plɔg gej na wan silinda tul we dɛn mek fɔ inspɛkt di insay dimɛnshɔn dɛn fɔ ol, bor, ɔ slot. Tipikli dɛn kin yuz am fɔ go/nɔ-go mɛzhɔmɛnt, wan plɔg gej de chɛk if wan pat mit spɛsifikɛd tolɛreshɔn dɛn bay we i de disayd if i fit insay di akseptabl dimɛnshɔnal rɛnj. Plɔg gej dɛn de insay difrɛn kayn dɛn, lɛk plein plɔg gej, taper plɔg gej, ɛn trɛd plɔg gej, ɛni wan tayla fɔ spɛshal aplikeshɔn dɛn. Dɛn strɔng, dɛn izi fɔ yuz, ɛn dɛn fayn fɔ ay-prɛsishɔn industri dɛn lɛk ɔtomotiv ɔ aerospace manufacturing.

Pin Gej .:

Pin gej dɛm, na di ɔda say, na smɔl silinda pin dɛm we kin kam insay sɛt ɛn dɛn kin yuz dɛn fɔ prɛsis dimɛnshɔnal mɛzhɔmɛnt, inklud di sayz ɛn rawndnɛs fɔ di ol dɛm. Nɔ lɛk plɔg gej, PIN gej dɛn nɔ de fɔs fɔ go/nɔ-go tɛst. Bifo dat, dɛn kin gi di rayt mɛzhɔmɛnt bay we dɛn put difrɛn pin saiz dɛn insay wan ol te dɛn rich wan snug fit. Pin gej dɛn kin yuz na tul ɛn day shɔp, kalibreshɔn lab, ɛn industri usay ɔlta-prɛsis mɛzhɔmɛnt impɔtant.

Ki Difrɛns dɛn .:

Di praymar distinkshɔn de insay usay dɛn de yuz am. Plɔg gej dɛn de gi wan baynary pas/fail rizɔlt, we de mek di inspekshɔn prɔses simpul, we PIN gej dɛn de gi ditayl dimɛnshɔnal data, we de alaw fɔ prɛsis mɛzhɔmɛnt fɔ di ficha dɛn. Plɔg gej dɛn tipikli mɔ robust ɛn fit fɔ ripit inspekshɔn, we PIN gej dɛn na dilikɛt ɛn bɛtɛ fɔ ditayl ɛvalueshɔn. Dɛn tu tul ya na impɔtant tin fɔ kɔntrol kwaliti bɔt dɛn pik dɛn bay di lɛvɛl we di prɛsishɔn ɛn di kayn inspekshɔn we dɛn nid.